Core Comptences

Why choose us

Jvtech, established for twelve years, has always upheld a mindset of endless learning and remains committed to being a constructive force in serving humanity. Starting from the minutiae, we meticulously craft each LSR (Liquid Silicone Rubber) precision component with dedication.

Our company boasts two seasoned LSR raw material scientists, one visiting professor in mold design, three mold experts, nine engineers specializing in process automation, and twelve quality engineers.

With a staff of over 200, our headquarters are located in Zhongshan, Guangdong, China, encompassing a factory area of 15,000 square meters. We possess a comprehensive in-house manufacturing supply chain and currently operate 70 LSR injection molding machines (including four 2k Molding).

Technical Competence

Jvtech’s technical competence can make your project delivery with the best way.

- LSR (Liquid Silicone Rubber) Molding

- Multi-Component Molding

- Multi-cavity Mold

- Professional Engineer

Reliable Quality

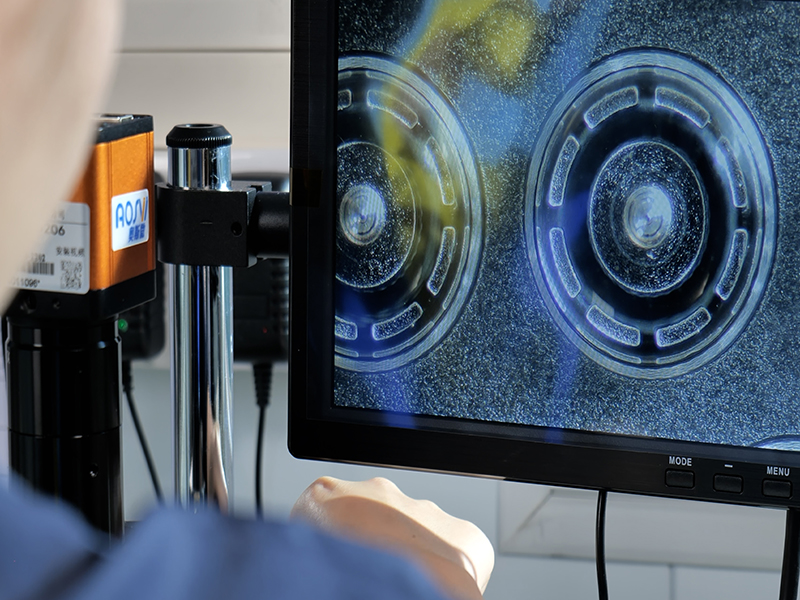

Cutting-Edge Inspection Equipment

To conduct our extensive range of inspections, We have ISO 13485/ISO 9001/ISO 14001/ISO 45001 and use a wide variety of advanced equipment, including:optical microscope, CCD, tear-resistant and pull-out detection, video microscope, VOC detector.

Environmental Testing

In order to improve the production capacity, we installed six high-power ovens in the post-curing room to meet the voc standards of European and American standards, with special personnel monitoring regularly and 24-hour continuous vulcanization.

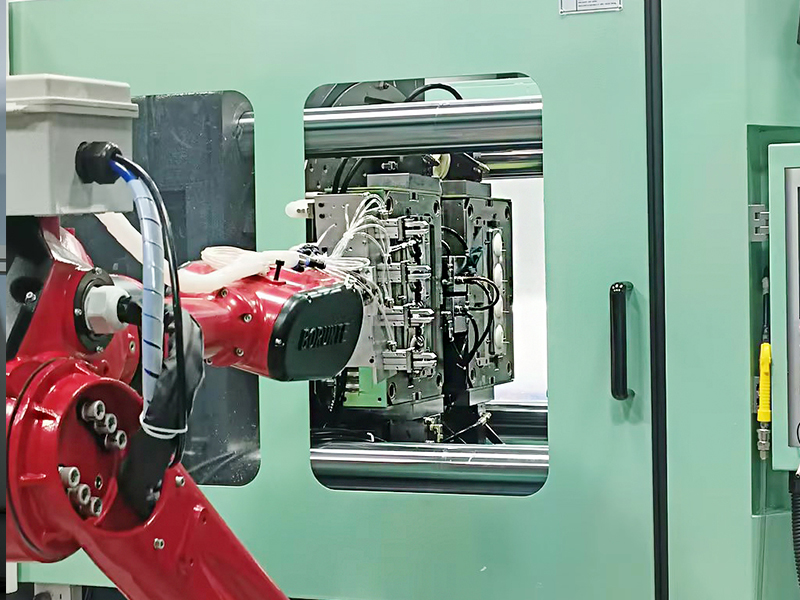

Smart Manufacturing

Fully promote automation and strictly abide by ISO standards for mass production. Equipped with a dust-free molding workshop and a 100,000-level dust-free sorting workshop, this is to achieve better project delivery of medical, babycare, and optical silicone rubber parts.

Information Security

As a OEM factory, the protection of project data is the most basic and important. Therefore, customers will be converted into internal codes, the workshop needs fingerprint confirmation to open the door, and the workers’ mobile phones will be collected at the designated place.

Focus on R&D

We have been deeply involved in China for more than ten years, and have a perfect supply chain system. We will invest 30% of our profits in automation every year, greatly reducing labor costs. Our philosophy is to work with customers to make products well and reassure consumers.

FAQ

Frequently Asked Questions

If you have other questions, please find the sales engineer on the contact us page.

While we do not provide a standalone product design service, we do offer Design for Manufacturing reviews on all approved orders. This means that we work with our clients to help them optimize their 2D and 3D drawings in order to improve manufacturability, resolve design conflicts and lower production costs.Read how to prepare your CAD drawings for manufacturing.

In order to provide an accurate and timely quote, we only accept 3D CAD files in STL, STEP or IGES format. 2D drawings with reference dimensions must be in PDF format. We must receive complete manufacturing information as part of this technical documentation.

Although direct comparisons are difficult, Jvtech’s prices will be typically 30-45% less for LSR injection mold parts when compared to suppliers in North America and Europe.

As compared to Chinese suppliers, we choose to not to compete on price but to offer the highest levels of quality, rapid response and professional results.

Quality parts can be made in as little as two weeks if you provide us with complete 2D and 3D CAD models. More complex parts requiring or other special features will take longer. Request a quote to get more accurate lead times based on your project.

As for shipping, most of our shipments are via sea transportation, which can take a month from China to your city.

Once your order is confirmed, we will perform a full Design for

Manufacturing (DFM) review to point out any issues that our engineers feel may affect the quality of your parts.

All incoming materials are inspected and verified with a suite of testing equipment.

Final inspection reports before shipment.

We have the ability to share inspection data with you in real-time so we can work together to address any quality issues you may have during production.

Our standard terms are Ex Works (EXW) for rapid prototyping and regular production orders. This means the customer is responsible for shipping, customs clearance and all other associated fees once the goods have left our premises.

For express shipments, we use Delivered Duty Unpaid (DDU), which means that the client is responsible for paying import duty when the goods arrive to your destination.

We guarantee our materials and workmanship based on the terms of the initial order and the information provided by you. Any disputes based on a subjective determination shall be brought to the attention of management who will act in good faith to provide you with complete satisfaction. Our continuing business relies on earning your confidence in our ability to meet and exceed any reasonable expectations.

We have no minimum order quantity, and we can quote base on your required batch quantity.

Let's start talking with us

Our value

Let’s build the future with innovation.

Jvtech has a team of experienced and skilled designer, engineer and technician. High quality standard, competitive price, on time delivery and responsible afer-sales service are the principle that we follow to develop the mutual trust and confidence with our domestic and international clients.

If you have any new design of products need to be tested and put on the market, please do not hesitate to contact us. We will get back to you as soon as possible.