Case of LSR Smart Manufacturing

Cases of Smart Manufacturing by Liquid Silicone Rubber Molding

Smart manufacturing, also known as Industry 4.0, leverages advanced technologies like automation, data exchange, and artificial intelligence to optimize production processes. This leads to increased efficiency, flexibility, and cost reduction while maintaining high product quality.

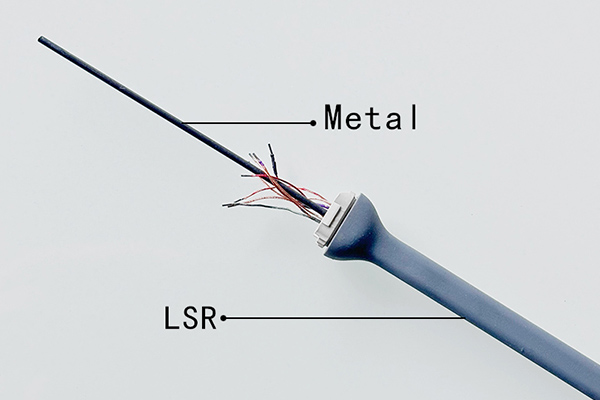

Liquid silicone rubber (LSR) is a versatile elastomer known for its biocompatibility, high thermal stability, and excellent mechanical properties. These characteristics make it ideal for various applications, particularly in the medical, automotive, and consumer goods sectors.

LSR molding is particularly well-suited for smart manufacturing due to its unique properties and processing advantages:

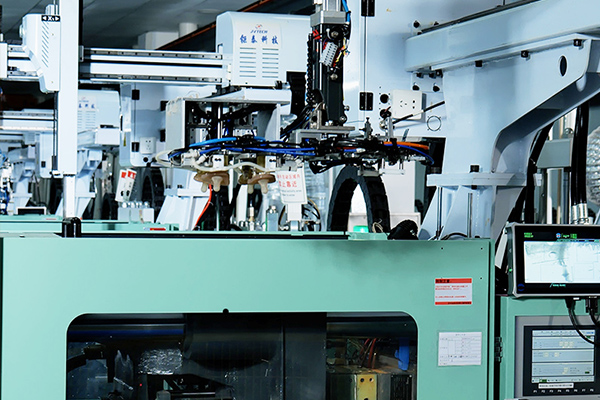

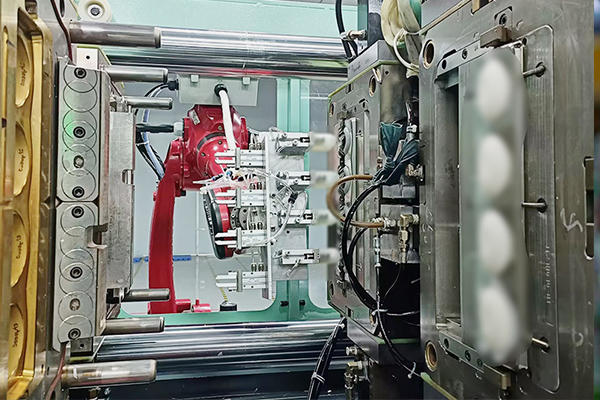

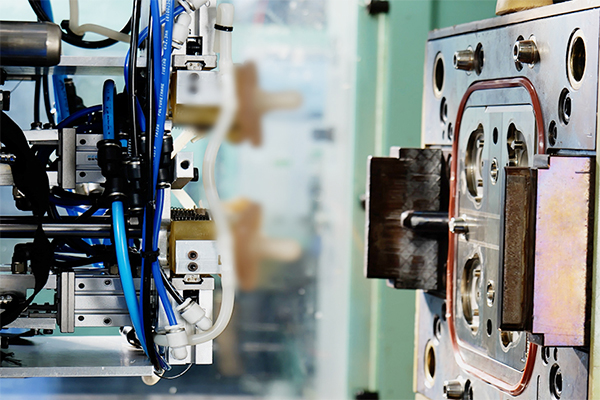

- Automation: LSR injection molding processes are easily automated, minimizing human intervention and reducing the risk of errors.

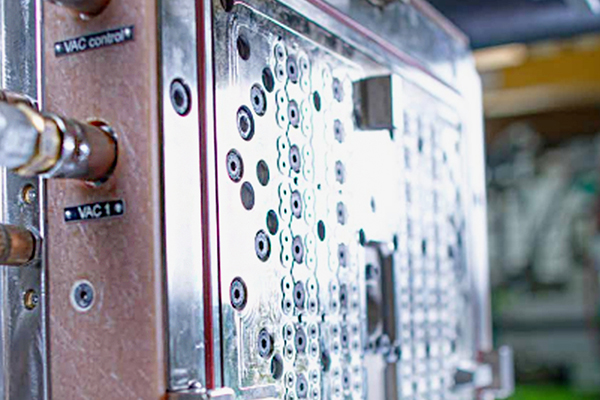

- Data Collection and Analysis: Sensors integrated into LSR molding machines collect real-time data on process parameters like temperature, pressure, and cycle time. This data can be analyzed to identify patterns, predict potential problems, and optimize production settings.

- Process Control: Automated feedback loops can adjust process parameters based on real-time data analysis, ensuring consistent product quality and maximizing efficiency.

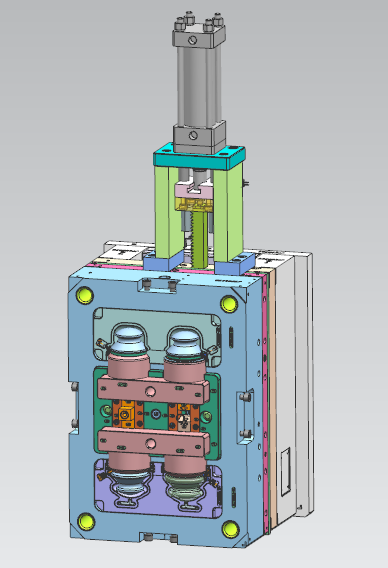

- Customization and Flexibility: LSR’s versatility allows for the production of complex geometries and multi-component parts, enabling manufacturers to quickly respond to changing market demands and customer requirements.

JVTech, a leading provider of LSR molding solutions, has successfully implemented smart manufacturing practices in various projects, including:

- Medical Device Manufacturing: JVTech utilized automated LSR injection molding and real-time process monitoring to produce high-precision medical components with exceptional quality and consistency.

- Automotive Component Production: JVTech leveraged data-driven insights to optimize LSR overmolding processes for automotive parts, resulting in increased efficiency and reduced waste.

- Consumer Goods Manufacturing: JVTech employed flexible LSR molding techniques to create customized consumer products with unique designs and functionalities.

- ……(Maybe your business)

By embracing smart manufacturing principles and leveraging the advantages of LSR molding, JVTech has established itself as a pioneer in the industry, delivering innovative solutions and exceeding customer expectations.

The combination of smart manufacturing and LSR molding presents a powerful opportunity for businesses to revolutionize their production processes. By adopting these technologies, companies can achieve greater efficiency, flexibility, and cost savings, while maintaining the highest standards of product quality and customer satisfaction.