In the context of modern manufacturing trends toward functional integration and refined performance, the technology of liquid silicone rubber (LSR) overmolding on metal inserts has become a key process in fields such as consumer electronics, medical devices, and automotive components. By integrating LSR with metal inserts directly inside the mold, this process not only retains the mechanical strength and structural support of the metal, but also adds silicone-specific properties such as high-temperature resistance, aging resistance, insulation, and sealing performance. It effectively addresses the limitations of using metal components alone in demanding environments.

This article will provide a detailed explanation of the principle of LSR overmolding, the critical aspects of DFM (Design for Manufacturability) review, and its importance in injection molding. Through a multi-angle, multi-level analysis, potential design defects and process challenges will be identified, followed by practical improvement recommendations. The goal is to reduce manufacturing cost and process difficulty while ensuring consistent quality and performance.

- Technical Fundamentals of LSR Overmolding on Metal Inserts

To fully understand the core logic of this process, it is necessary to clarify the material characteristics and bonding principles of both LSR and the metal inserts:

Liquid Silicone Rubber (LSR)

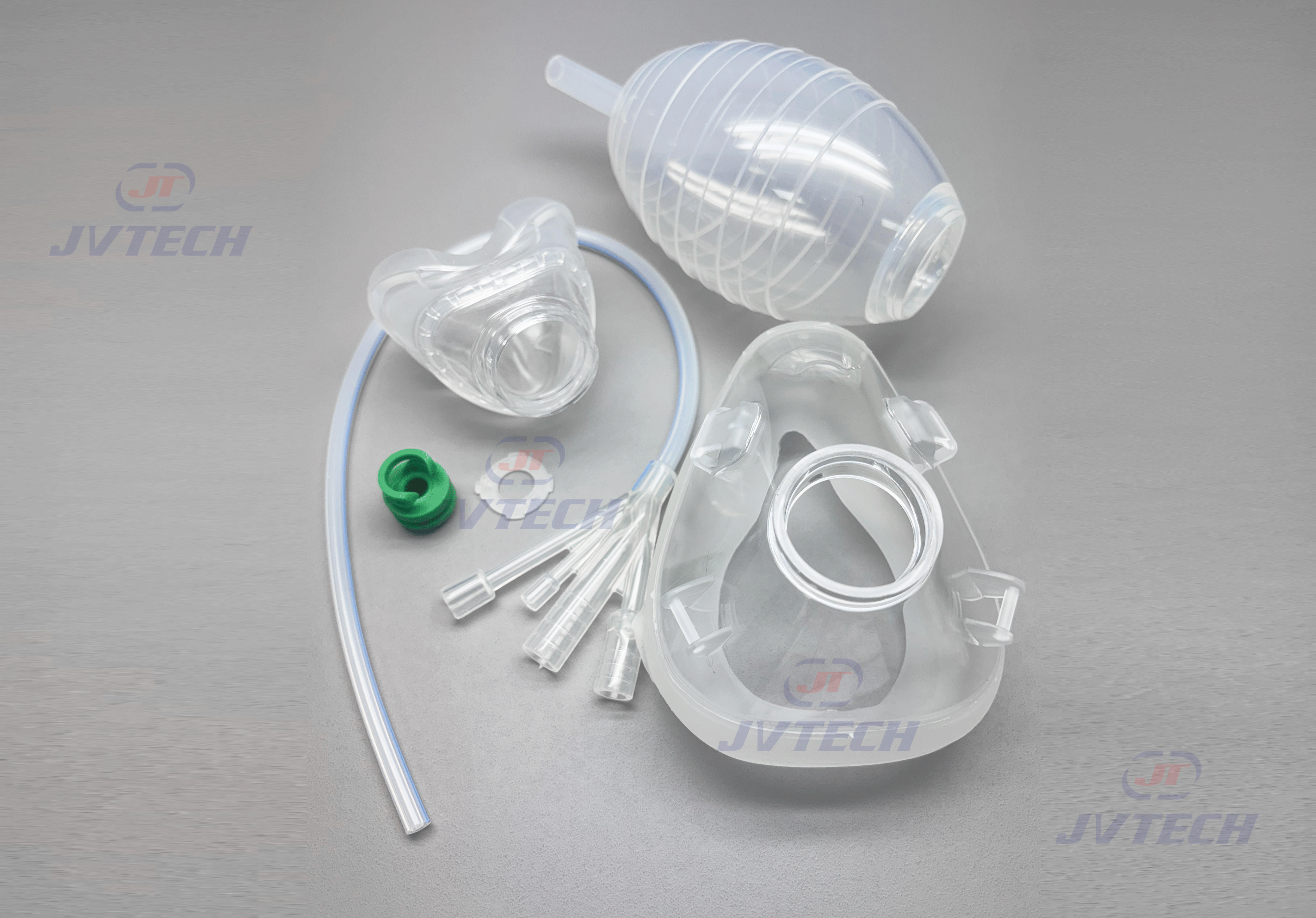

As a low-viscosity, high-flowability synthetic rubber, LSR cures quickly through crosslinking without requiring extremely high temperature or pressure. In addition to outstanding resistance to heat and aging, LSR also offers excellent biocompatibility and electrical insulation. This makes it suitable not only for complex and demanding environments but also for applications where stable encapsulation of precision parts is required.

Metal Inserts

Typically, rigid and stable materials such as brass, stainless steel, or galvanized steel are used as inserts. To ensure strong bonding with silicone, the metal surface must undergo pre-treatment before overmolding. Common methods include removing oils and oxides and increasing surface roughness. These treatments enhance interfacial adhesion, preventing issues such as debonding or delamination during later use.

Core Logic of the Process

LSR overmolding on metal inserts is not a simple material stacking process, but an in-mold integration of two materials. The sequence is as follows:

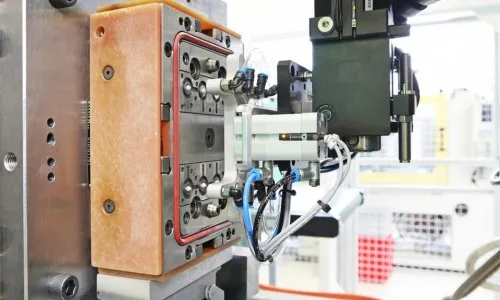

The pre-treated metal insert is precisely positioned and fixed inside the mold cavity (often with specially designed positioning structures to prevent displacement).