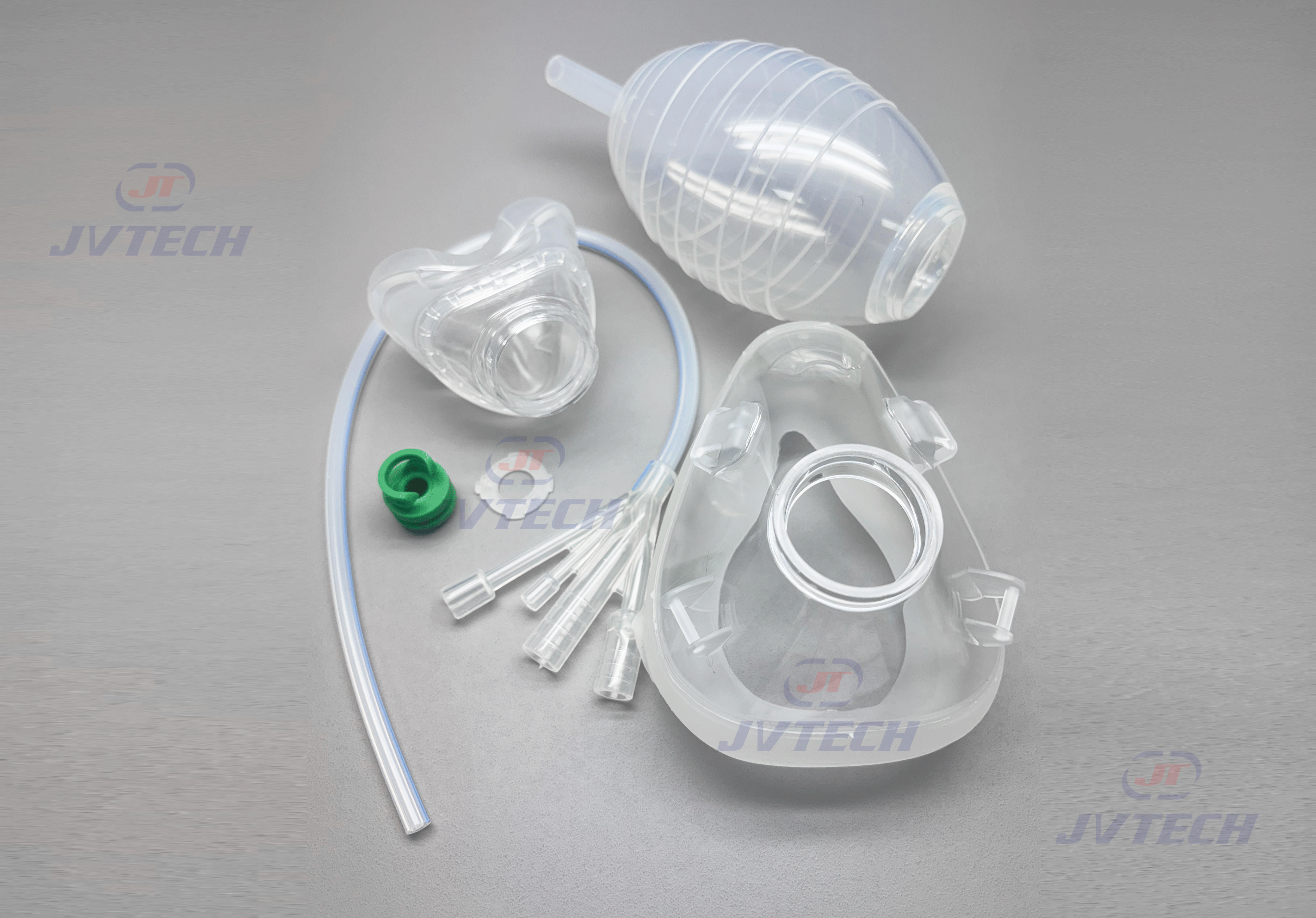

In modern manufacturing, Liquid Silicone Rubber (LSR) has become an indispensable key material in many high-end manufacturing fields due to its unique performance advantages. Whether it is for medical devices that require strict biocompatibility, consumer electronics that pursue an ultimate user experience, or automotive components that operate in harsh working environments, LSR can provide excellent solutions.

Faced with a wide range of LSR brands and models available on the market, how to make the most suitable selection has become a difficult problem for many engineers and procurement decision-makers. This article will provide you with a complete material selection framework to help you find the optimal solution in the complex world of materials.

一、Decoding LSR’s Performance Code: In-Depth Analysis of Key Parameters

To make informed material selection decisions, it is first necessary to gain a deep understanding of LSR’s core performance parameters.These indicators are not only a reflection of material performance, but also an important basis for predicting product performance.

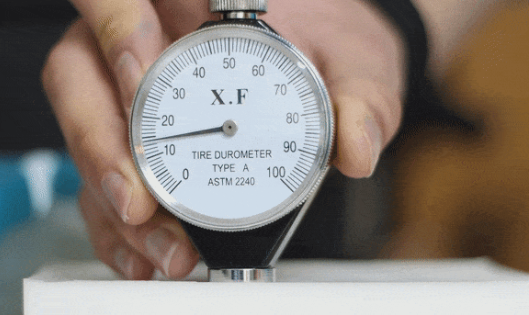

As one of the most intuitive parameters, hardness directly affects the product’s user experience. From the soft touch required for infant and toddler products (Shore A 10-30) to the high-hardness support needed for industrial seals (Shore A 70-80), different application scenarios have vastly different requirements for hardness. Importantly, the selection of hardness needs to match the product’s structural design, rather than simply pursuing extreme values.

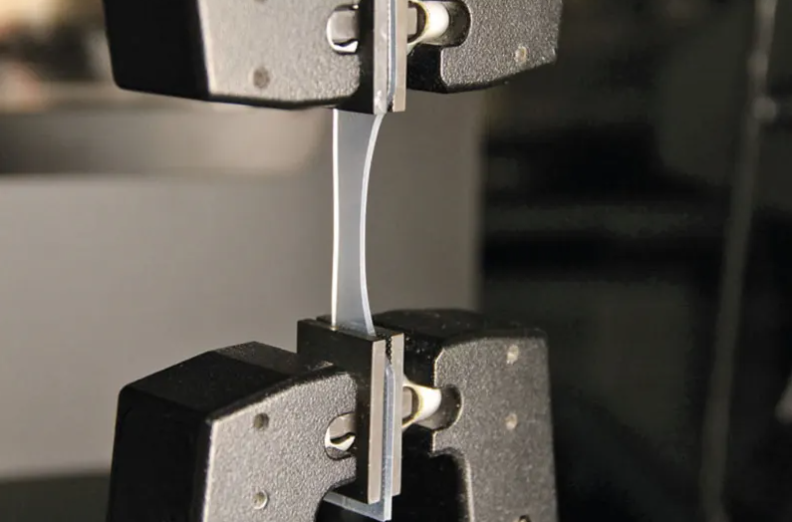

In terms of mechanical properties, tear strength and tensile strength are two key indicators. In practical applications, we often encounter cases like this: a delicately designed thin-walled part frequently gets damaged during the assembly process due to insufficient tear strength of the material. After upgrading the material’s (tear strength) from 25 N/mm (for general-purpose grades) to 40 N/mm (for high-performance grades), the problem was solved easily.

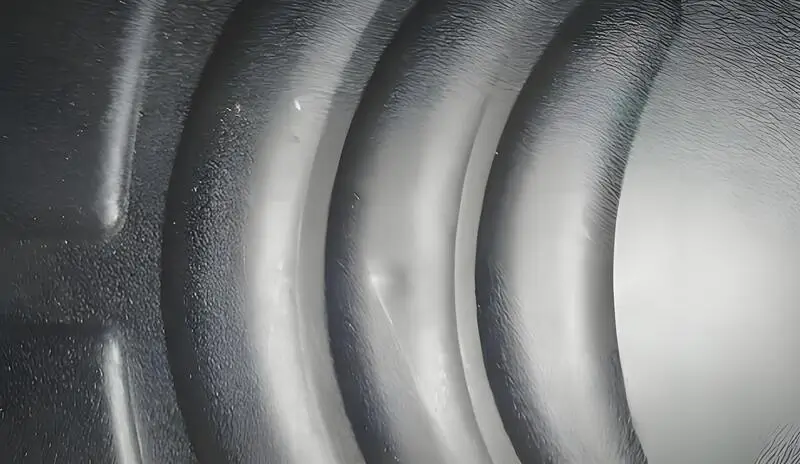

Process performance also can not be ignored. Flowability directly determines a material’s ability to fill complex molds. High-flowability LSR can significantly reduce injection molding pressure, as well as lower the risks of internal stress and flash in the final product. Meanwhile, the stability of shrinkage rate is crucial to product dimensional accuracy. High-quality LSR brands can control the shrinkage rate deviation between batches within 0.2%, providing reliable guarantee for precision manufacturing.

Certification qualification is the access threshold for material selection. For medical applications, USP Class VI and ISO 10993 certifications are mandatory, while food contact applications require compliance with FDA regulations and EU food contact regulations. These certifications are not only a necessary condition for market access, but also an important guarantee for product quality and safety.

二、Analysis of Mainstream LSR Brands: Market Pattern and Advantages

After years of development, the global LSR market has formed a relatively stable brand landscape. Understanding the characteristics and advantages of each brand helps to quickly narrow down the suitable material selection range.

Tier 1: Technology Leaders

Wacker excels in the field of medical-grade and optical-grade LSR, and its SILPURAN® series has become the first choice for high-end medical devices. Typical applications include: implantable medical devices, endoscopic components, optical sensor seals, etc.

Momentive is renowned for its comprehensive product portfolio and has extensive applications in the automotive and industrial sectors. Its self-adhesive technology is particularly suitable for manufacturing complex components such as automotive engine seals and new energy battery pack sealing systems.

Tier 2: Specialists in Professional Fields

Shin-Etsu’s products are renowned for their excellent stability and are highly favored in the consumer electronics and precision manufacturing sectors. Typical applications include: waterproof seals for smartphones, components of smart wearable devices, high-precision industrial seals, etc.

Dow, leveraging its strong industrial chain integration capabilities, delivers more competitive prices while ensuring product quality. It is widely used in high-volume production scenarios such as medical device housings and household appliance seals.

Tier 3: Cost-Effective Options

Domestic brands represented by Bluestar have made remarkable progress in recent years. They have performed excellently in fields such as general-purpose seals and daily consumer goods. Their service system with rapid response and cost advantages has provided many manufacturers with new options.

三、Authoritative Comparison and Selection Decision-Making System

LSR Selection FAQ: R&D Q&A

Q1: My product belongs to the [specific industry]. What should I prioritize when selecting LSR?

If it belongs to the medical industry: It is imperative to prioritize grades with medical-grade certifications (such as ISO 10993, USP Class VI). This is not only related to the registration and approval of the final product, but also the primary guarantee for patient safety.

Q2: My product will be sold in the [target market]. What specific regulatory and environmental requirements do I need to meet?

European Union (EU) Market: What is extremely easy to overlook is the biocompatibility report of semi-finished products (such as rubber granules). Many manufacturers only provide reports after vulcanization, but contaminants introduced during the processing may cause your product to fail the tests. You must request biocompatibility declarations and test reports at the raw material level from your supplier.

Q3: In my industry, what specific requirements are often overlooked besides the standard parameters?

If it belongs to the medical industry: One of the most commonly overlooked aspects is the biocompatibility report of semi-finished materials (such as silicone granules). Many manufacturers only provide reports after vulcanization, but contaminants introduced during processing may cause your product to fail the tests. You must request biocompatibility declarations and test reports at the raw material level from your supplier.

Guide to Matching Functional Applications with Material Properties

Q1: How to simplify assembly and reduce costs?

Choosing self-adhesive LSR allows direct bonding with plastic parts, eliminating the need for glue and additional processes.

Q2: When is it necessary to use high tear-resistant materials?

When a product features a thin-walled design, requires frequent disassembly, or has sharp-angled structures, a material with a tear strength of >30 N/mm should be selected.

Q3: How to quickly select the appropriate hardness?

Match directly according to the product’s functional requirements. For example: Ultra-soft materials (Shore A 10-30) should be selected for baby bottle nipples to ensure comfort during use.

Explanation of Decision Key Points

Through the above decision-making process, you can quickly narrow down the selection range. But the final decision still needs to take the following key factors into account:

Technical Support Capabilities: An excellent supplier should be able to provide comprehensive support ranging from material selection, mold design to process optimization.

Supply Chain Stability: Ensure the consistency between material batches and establish a reliable supply guarantee system.

Total Cost of Ownership (TCO): In addition to the unit price of materials, it is also necessary to comprehensively consider production efficiency, yield rate, and maintenance costs.

Conclusion

In the selection process of liquid silicone rubber (LSR), there is no one-size-fits-all standard answer. The key lies in finding the material that best fits the application requirements. This requires not only an understanding of material properties, but also an in-depth comprehension of product scenarios and process requirements.

As a long-term partner of multiple international chemical brands, Jvtech is well aware of the importance of material selection to product success. We are willing to leverage our years of practical industry experience to provide customers with comprehensive technical support, ranging from material selection to process optimization.

If you are seeking an LSR application solution, please feel free to contact us, and we will work together to explore the optimal material path.