Liquid Silicone Rubber (LSR) has become a highly versatile material, widely used across various industries. One of its primary applications is in the manufacturing of seals and gaskets, where its unique properties make it an ideal choice for ensuring reliable sealing performance. This article explores the advantages and applications of LSR in seals and gaskets, highlighting its effectiveness, durability, and versatility in meeting diverse sealing requirements.

Understanding Liquid Silicone Rubber (LSR)

Liquid Silicone Rubber (LSR) is a synthetic elastomer characterized by high flexibility, heat resistance, and chemical inertness. It is produced through precision mixing and injection molding processes, ensuring consistent and uniform properties. LSR is well known for its excellent thermal stability, electrical insulation, and resistance to environmental factors such as UV radiation and moisture.

Advantages of LSR in Seals and Gaskets

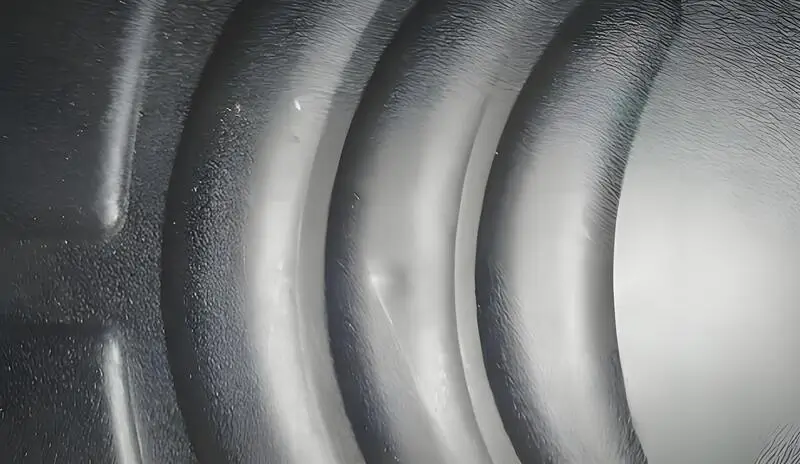

Excellent Sealing Performance

The inherent flexibility of LSR allows it to conform to irregular surfaces, ensuring tight seals that prevent leaks and contamination.

Wide Temperature Range

LSR demonstrates outstanding thermal resistance, maintaining sealing performance over a broad temperature range from -50°C to 250°C, making it suitable for both low- and high-temperature applications.

Chemical Resistance

LSR resists degradation caused by exposure to chemicals, oils, and solvents, ensuring long-term sealing integrity even in harsh environments.

Durability and Longevity

LSR seals and gaskets are highly durable, with resistance to wear, tear, and compression set, thereby extending service life and reducing maintenance needs.

Versatility

LSR can be formulated to meet specific requirements for hardness, color, and transparency, making it suitable for a wide range of sealing applications across industries.

Applications of LSR Seals and Gaskets

Automotive Industry

LSR seals and gaskets are widely used in automotive applications such as engine components, fuel systems, and electrical connectors, where reliable sealing is critical to performance and safety.

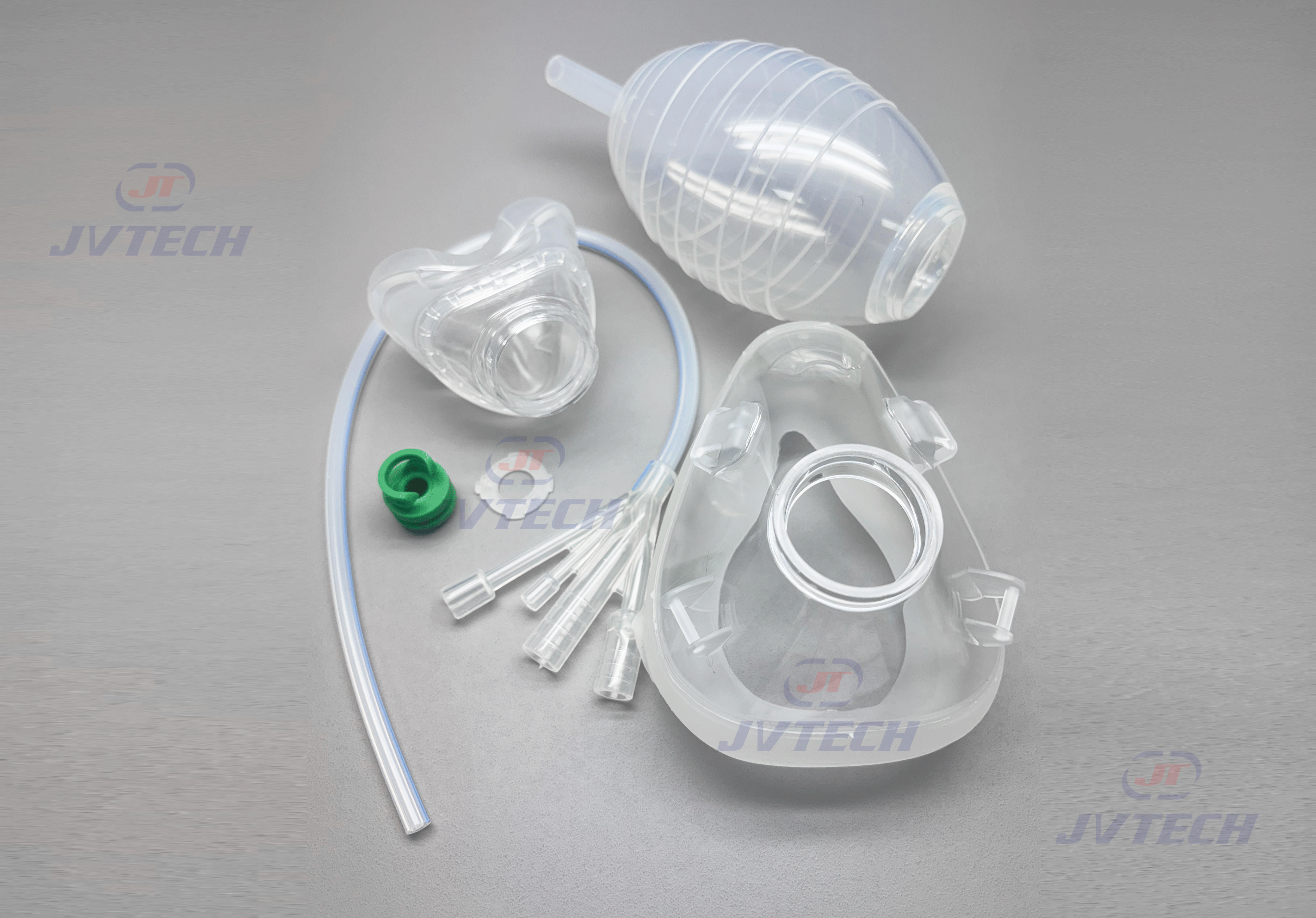

Medical Devices

The biocompatibility and stability of LSR make it an ideal material for medical device applications, such as seals in surgical instruments, fluid transfer systems, and implantable devices, ensuring patient safety and regulatory compliance.

Electronics

LSR seals and gaskets play a crucial role in electronic enclosures, connectors, and displays, protecting against moisture, dust, and electromagnetic interference (EMI).

Industrial Machinery

LSR seals and gaskets are used in various industrial machinery and equipment, including pumps, valves, and hydraulic systems, to prevent fluid leakage and contamination, ensuring reliable and efficient operation.

Conclusion

Liquid Silicone Rubber (LSR) offers unmatched sealing performance, durability, and versatility, making it the preferred material for seals and gaskets in a wide range of industrial applications. Its unique combination of properties—including flexibility, high-temperature resistance, chemical inertness, and biocompatibility—ensures reliable sealing solutions that meet the most demanding performance requirements. As the demand for high-performance sealing solutions continues to grow, LSR remains at the forefront, driving innovation and delivering superior sealing performance in critical applications.

For more information on liquid silicone rubber sealing solutions and custom applications, please contact us.