Recently, a trend from air up has been sweeping the globe, attracting the attention of many young people. Its iconic water bottle with a circular scent pod is not only unique in appearance but also achieves surprising innovations in functionality.

Product highlight: Taste the fragrance

The most distinctive feature of the air up water bottle is that its bottle opening is designed with a dedicated scent pod, which can release fragrance during drinking, allowing ordinary tap water to take on various flavors such as apple, orange and even iced coffee. This idea was initially put forward by several university students in Munich. Today, it has become a best-selling product worldwide and has received investments from well-known figures and companies including Ashton Kutcher and PepsiCo.

Made in Europe: A Model of Short-Chain Collaboration

Despite air up’s international reputation, its founder Fabian Schlang and his team still adhere to the concept of “Designed in Germany, Manufactured in Austria”. The entire production radius of the water bottle is controlled within 140 kilometers: the required materials are supplied from Burghausen, the drinking spouts are produced by RICO in Austria, Greiner completes the bottle manufacturing and final assembly within a 30-minute drive, and finally, the air up team in Munich is responsible for marketing.

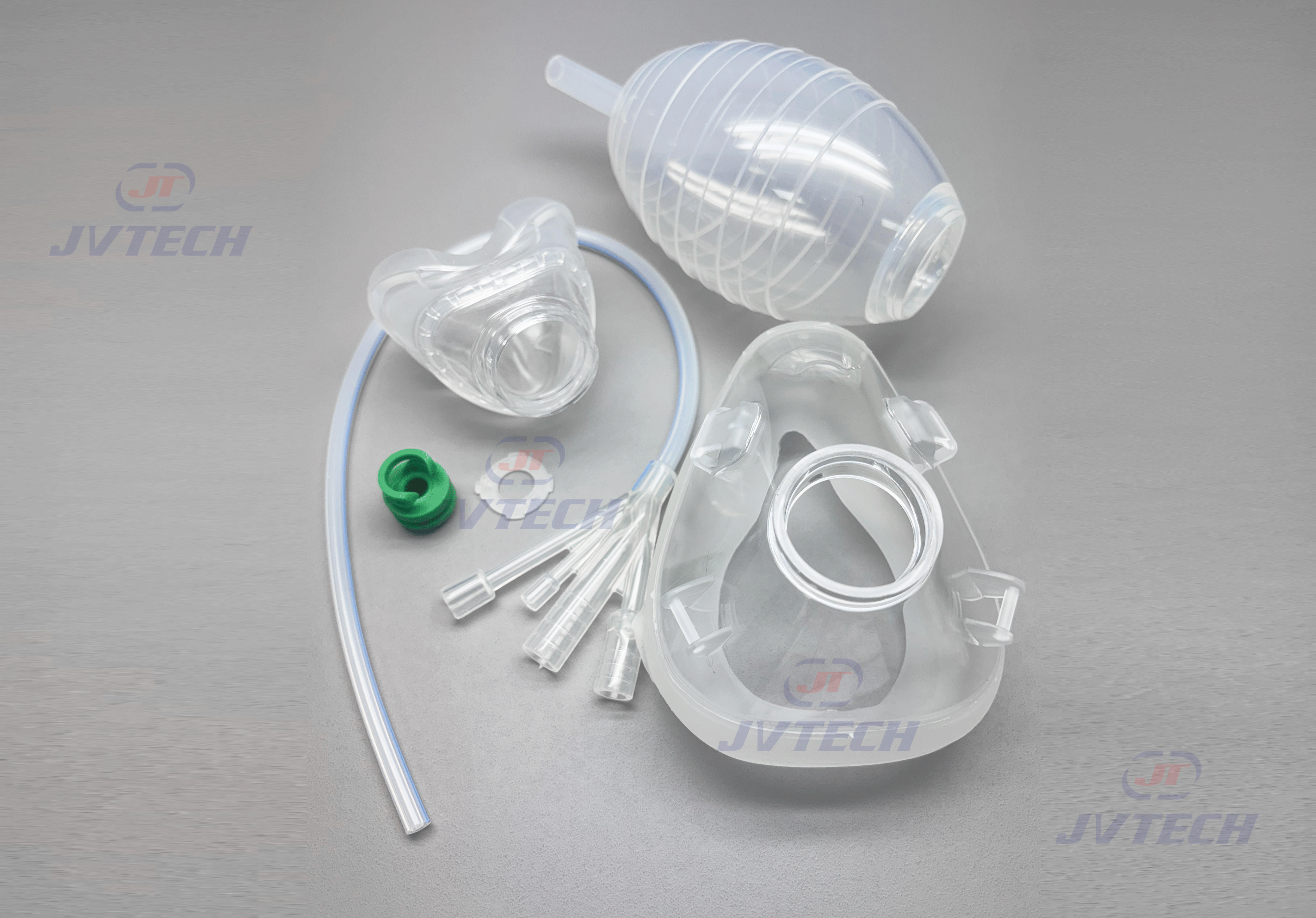

Core technology: Silicone drinking spout

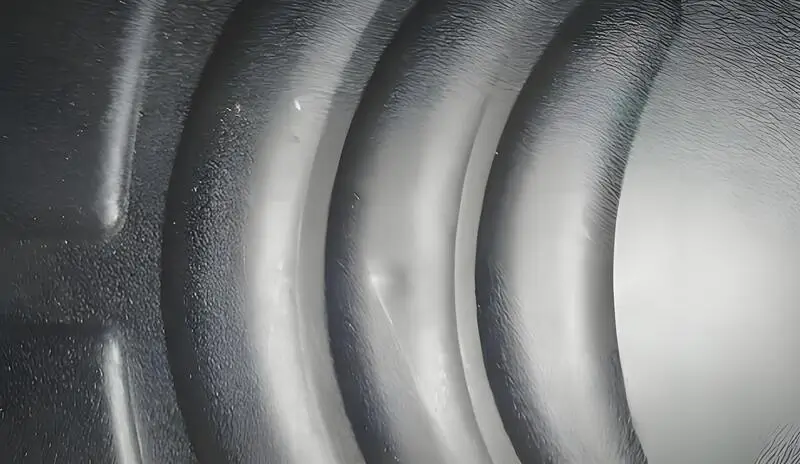

The success of the air up water bottle is inseparable from its core component—the silicone drinking spout. This component not only serves a sealing function but also locks in the fragrance from the scent pod like a perfume bottle does. When the bottle cap is opened, the wavy edge of the drinking spout slightly lifts the scent pod, and two small holes with a diameter of less than 1 mm are precisely aligned. This allows external air to flow through the scent pod during drinking, delivering a rich flavor.

Multi-Cavity Injection Molding: Efficient Manufacturing of Complex Structures

Integrating multiple functions into a small drinking spout is the result of collaborative development by multiple parties. RICO has achieved efficient production of drinking spouts using an 8-cavity mold, leveraging complex 3D geometric molds combined with the excellent fluidity and processability of silicone.

Colorful designs, quick response to the market

In addition to its functionality, the air up water bottle is also appealing for its diverse exterior colors. Mr. Schlang pointed out: “The colors of our products are updated very quickly.” At least 27 different colors of drinking spouts will be launched this year alone. In a professional color laboratory, the team precisely matches the colors of the silicone to ensure that the injection-molded finished products are completely consistent with the design intent.

As a professional supplier in the field of liquid silicone rubber materials and products, Jvtech Silicone continues to pay attention to such innovative applications. Leveraging our technical accumulation in liquid silicone rubber formulation, precision injection molding, and color matching, we are committed to providing customers with safe, environmentally friendly, and color-diverse high-end silicone solutions, promoting consumption innovation and industrial upgrading.