Liquid Silicone Rubber (LSR) is widely used in the injection molding field due to its non-toxic and environmentally friendly properties. Whether it’s a silicone water bottle combined with metal or goggles made from rubber and plastic, LSR is omnipresent in daily life, often as a key component of composite material products. Such products usually require insert molding or overmolding processes. So, what is insert molding? What is overmolding? And how are these processes related to LSR products? This article will guide you through the OEM process of LSR insert molding to help you choose the most suitable manufacturing partner.

Is Insert Molding the Same as Overmolding?

In short, insert molding and overmolding share the same basic concept but differ slightly in the production process. Both aim to combine two or more materials, typically using harder materials like metal or plastic as the base structure or component, which is then overmolded with softer materials such as rubber or silicone. A common example is kitchenware or hardware items with silicone handles. The main difference is that overmolding can inject two or more materials in a single step, while insert molding usually involves injecting only one material. This distinction also reflects their respective advantages: overmolding is suitable for producing multi-color or multi-material products, while insert molding is better suited for high-volume production of less complex items.

Advantages of Liquid Silicone Rubber Material

Excellent Anti-Slip Properties and Feel

Compared to metals and certain plastic rubbers, silicone offers excellent elasticity, water resistance, acid and alkali resistance, and skin-friendly properties. Overmolding it onto metal or plastic surfaces can isolate foreign matter, extend product life, and significantly enhance the user’s grip experience. Additionally, LSR does not require the addition of vulcanizing agents during production and maintains high cleanliness, making it ideal for products that contact skin or are implantable, such as food-grade and medical-grade items like pacifiers and silicone tubes.

Wide Applicability

Although LSR is inherently soft, its physical properties such as elasticity and hardness can be flexibly adjusted by modifying the raw material ratio. For example, it can be used to produce pacifiers with a Shore hardness of 20A or silicone shoe soles with a hardness of up to 80A. Beyond medical and food applications, LSR is also widely used in automotive parts, aerospace, and electronic insulation components due to its excellent waterproofing, acid and alkali resistance, and low-temperature tolerance (down to -100°C), demonstrating high plasticity and adaptability.

Compliance with International Environmental Standards

Although plastic rubber is produced in large quantities and is low-cost, it may pose toxicity risks if misused. In contrast, LSR is explicitly defined as a green and environmentally friendly material, free from harmful substances such as phthalates and halogens. It complies with stringent regulations like the EU’s RoHS and REACH, meeting the high environmental standards of developed countries and serving as an ideal solution for companies pursuing sustainable production.

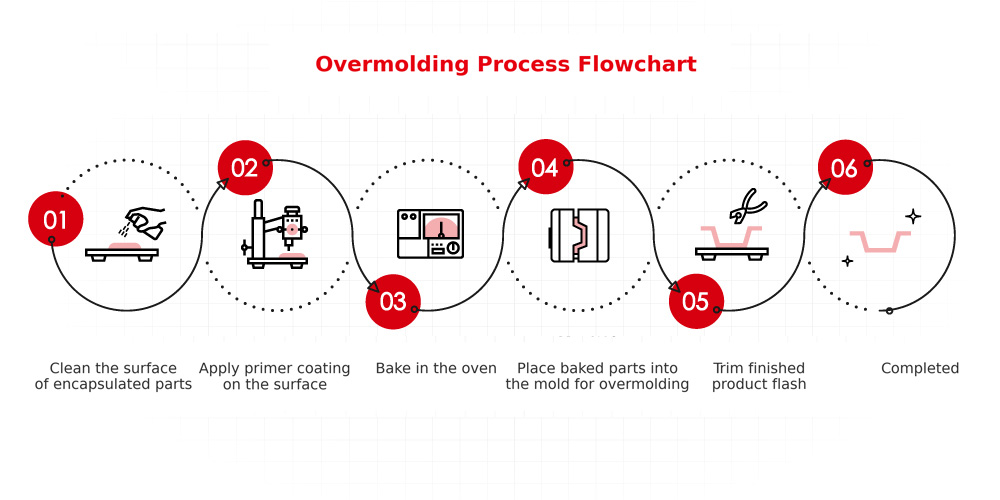

Insert Molding Process

1. Cleaning the Surface of the Insert Part

Since LSR has a melting point of around 130°C, the insert part must withstand higher temperatures to avoid deformation. Keeping its surface clean is crucial to ensuring final product quality.

2. Applying Primer

Primer enhances the adhesion between silicone and the substrate. Before insert molding, a layer of primer must be evenly applied to the surface of the insert part. Accuracy in this step can prevent residual adhesive issues later.

3. Baking Process

After applying the primer, the part is placed in an oven for drying, promoting a chemical reaction at the appropriate temperature to enhance bonding.

4. Placing the Insert Part into the Mold and Injection Molding

The insert part is positioned in the mold slot, and injection molding can begin. Manufacturers with automated equipment can achieve continuous production without manual intervention.

5. Deflashing

Finished products after demolding often have slight flash, which requires manual removal to ensure dimensional accuracy. Proper mold design can significantly improve the efficiency of this step.

Typical Applications of Insert Molding Products

Automotive and Motorcycle Parts

Vehicles consist of numerous parts, from small to large and simple to complex, requiring materials that can withstand cold, heat, impact, and vibration. Insert molding technology can combine metal and plastic rubber into integrated components such as sensors and gears, significantly improving production efficiency and product reliability.

Daily Use Products

Insert molding products are everywhere in daily life, such as scissors, plugs, and shoe materials. This process replaces traditional heating and pressing methods, improving product precision and bond strength while reducing waste rates and overall costs, better meeting market expectations for high-cost-effective daily goods.

Professional Electronic Components

As electronic components become increasingly precise and diverse, insert molding can provide impact-resistant, waterproof, and dust-proof protection for circuit boards and sensitive electronic panels, shielding them from moisture, dust, and electromagnetic interference, ensuring stable operation in complex environments.

Conclusion

Insert molding offers unique advantages in improving product precision, reducing production time, and lowering costs. However, it places high demands on mold design and manufacturing capabilities, and is not suitable for all products. Therefore, collaborating with an experienced liquid silicone rubber (LSR) partner at the early stage of a project is essential to determine the optimal solution. In addition to insert molding, processes such as die-cutting, compression molding, and overmolding should also be selected based on product characteristics.

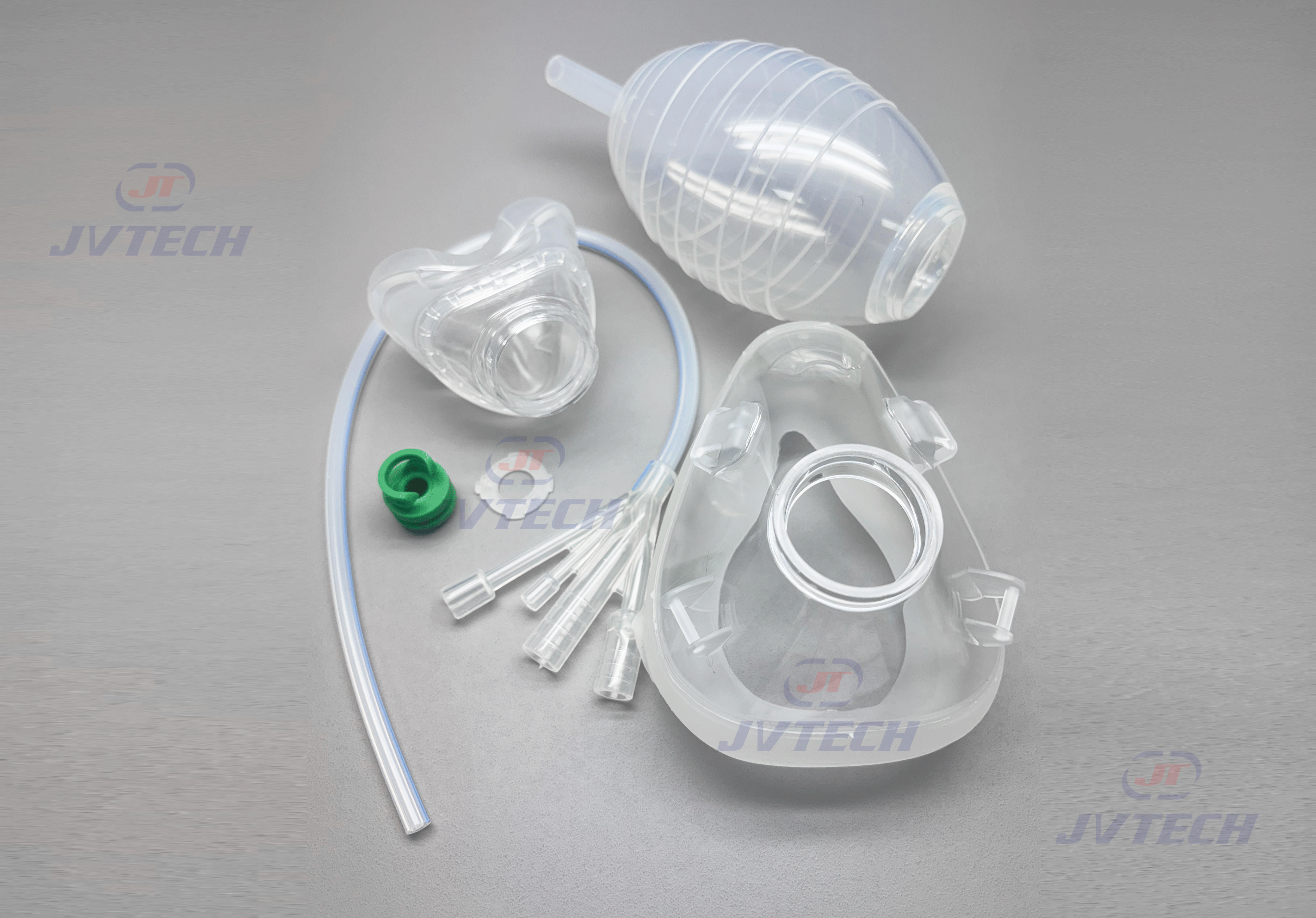

Jvtech focuses on LSR molding and contract manufacturing, with deep expertise in liquid silicone rubber injection molding, mold design and development, and material applications. Equipped with cleanroom facilities and a fully integrated testing laboratory, we provide flexible support across multiple molding and insert molding techniques, delivering end-to-end services from design consultation and prototyping to mass production. This ensures consistent quality and strong competitiveness for our clients’ products.

The company has been certified to ISO 9001, ISO 14001, ISO45001, and ISO 13485 international quality management systems. With proven experience in industries such as medical, maternal & infant care, electronics, and industrial components, Jvtech is able to provide efficient, reliable, and customized manufacturing solutions tailored to different product needs. We are committed to being your trusted LSR partner, and we welcome you to collaborate with us to explore more possibilities.