From Battery Packs to Electronic Modules, LSR is Quietly Enhancing the Vehicle’s “Immune System”

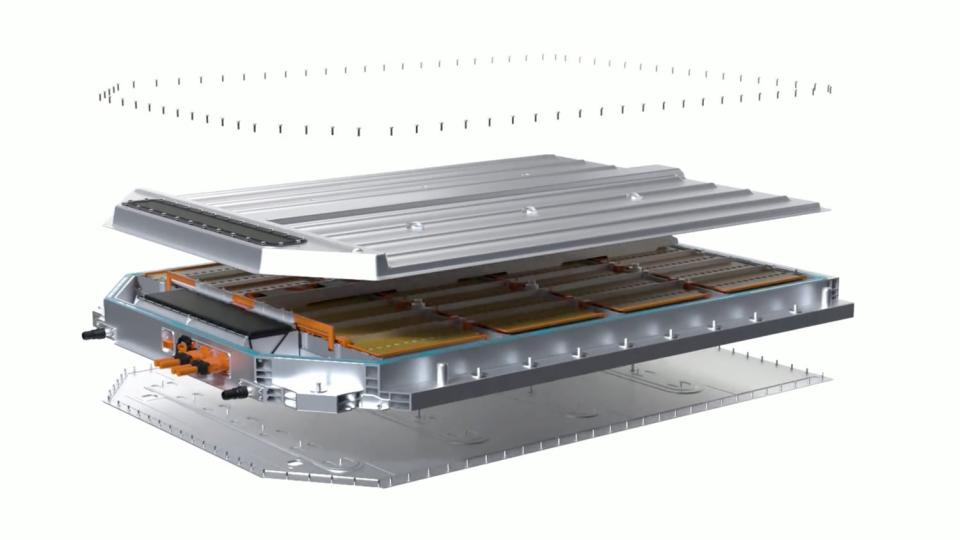

In the relentless pursuit of extreme range and performance, the New Energy Vehicle (NEV) powertrain—comprising the battery, electric motor, and electronic controls—faces unprecedented rigorous demands. Acting as the vehicle’s “heart” and “nerve center,” these systems generate significant heat during operation while simultaneously resisting external intrusions like rainwater, dust, and chemicals. This places higher demands on their protective “sealing systems,” where traditional rubber seals are increasingly revealing their limitations in lifespan and performance under persistent high temperatures, pressure, and chemical exposure.

一、When Traditional Materials Hit Performance Limits

Consider these scenarios,battery pack temperatures soaring during a fast charge on a hot summer day; coolant circulating in sub-zero winter conditions; power electronics handling hundreds of amps of current instantaneously. What does this mean for sealing materials?

Temperature Resistance Challenge: Traditional rubbers (like EPDM or silicone millable gums) typically withstand continuous temperatures from -40°C to 150°C. However, the adoption of 800V high-voltage platforms and fast-charging technologies can push local transient temperatures easily beyond 200°C, leading to material hardening, cracking, loss of elasticity, and ultimately, seal failure.

Aging and Reliability: Constant exposure to high heat, humidity, and coolant corrosion accelerates the aging of traditional materials, making it difficult for their sealing lifespan to match the vehicle’s required service life (often over 10 years).

Complex Geometry and Bonding Difficulties: Modern automotive electronics feature intricate designs often requiring seals to be molded directly onto engineering plastic (e.g., PA, PBT) housings. Traditional materials, with poor adhesion and insufficient processing precision, struggle to achieve perfect, “gapless” sealing.

These pain points directly impact vehicle operational safety, service life, and the owner’s experience. The industry urgently needs a new material solution that breaks through these performance ceilings.

二、The Game Changer: The Technical Advantages of Liquid Silicone Rubber (LSR)

Liquid Silicone Rubber, a high-performance elastomer, is emerging as the ideal choice for high-end automotive sealing systems due to its exceptional inherent properties.

1、Superior Temperature Resistance & Stability

LSR operates reliably from -50°C to 250°C, effortlessly handling extremes from deep freeze to intense heat. Its backbone consists of stable siloxane bonds, granting it excellent inherent resistance to aging, weathering, and UV radiation. This ensures long-term stability of the seal, significantly extending the service life of critical components.

2、Excellent Electrical Insulation & Flame Retardance

As a natural insulator, LSR effectively protects high-voltage battery connectors, control modules, and other core electronics, preventing short circuits caused by moisture ingress. Furthermore, it possesses inherent flame retardancy (achieving ratings like UL94 V-0), adding an extra layer of safety.

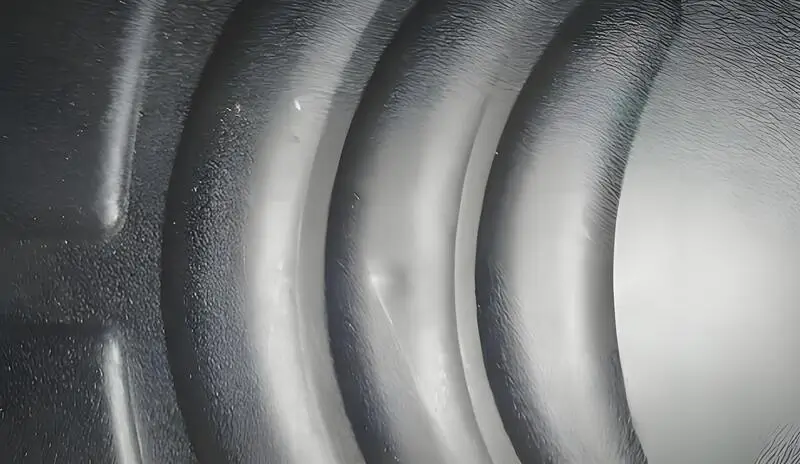

3、Unmatched Processability & Bonding Capability

LSR is injection molded, offering excellent flow properties that perfectly fill micron-level mold gaps, ensuring high dimensional accuracy and consistency. Crucially, through precise mold and process control, it achieves a strong “two-shot overmolding” bond with various engineering plastics. This creates a molecular-level bond, (eradicating leakage risks from poor adhesion) and achieving true “integral sealing.”

三、Application Scenes: Where is LSR Protecting Core Areas?

Liquid Silicone Rubber finds critical applications across key systems in New Energy Vehicles:

Battery Pack Housing Seals: As the first line of defense for the battery system, LSR gaskets ensure the overall airtightness and watertightness of the pack, effectively blocking external moisture and contaminants, safeguarding the cells in a dry, clean environment.

High-Voltage Charging & Connection Interfaces: In charging sockets and high-voltage harness connectors, LSR provides reliable waterproof insulation, ensuring absolute safety during high-current transfer.

Electronic Control Units (ECU/VCU/BMS): Protecting these “brains” and “commanders” from water, dust, and vibration, LSR’s precise overmolding offers comprehensive protection for delicate PCB boards.

Sensor Housings/Boots: For various sensors (pervasive throughout the vehicle body) (e.g., radar, cameras), LSR housings/boots ensure accurate sensing and reliable data transmission even in harsh environments.

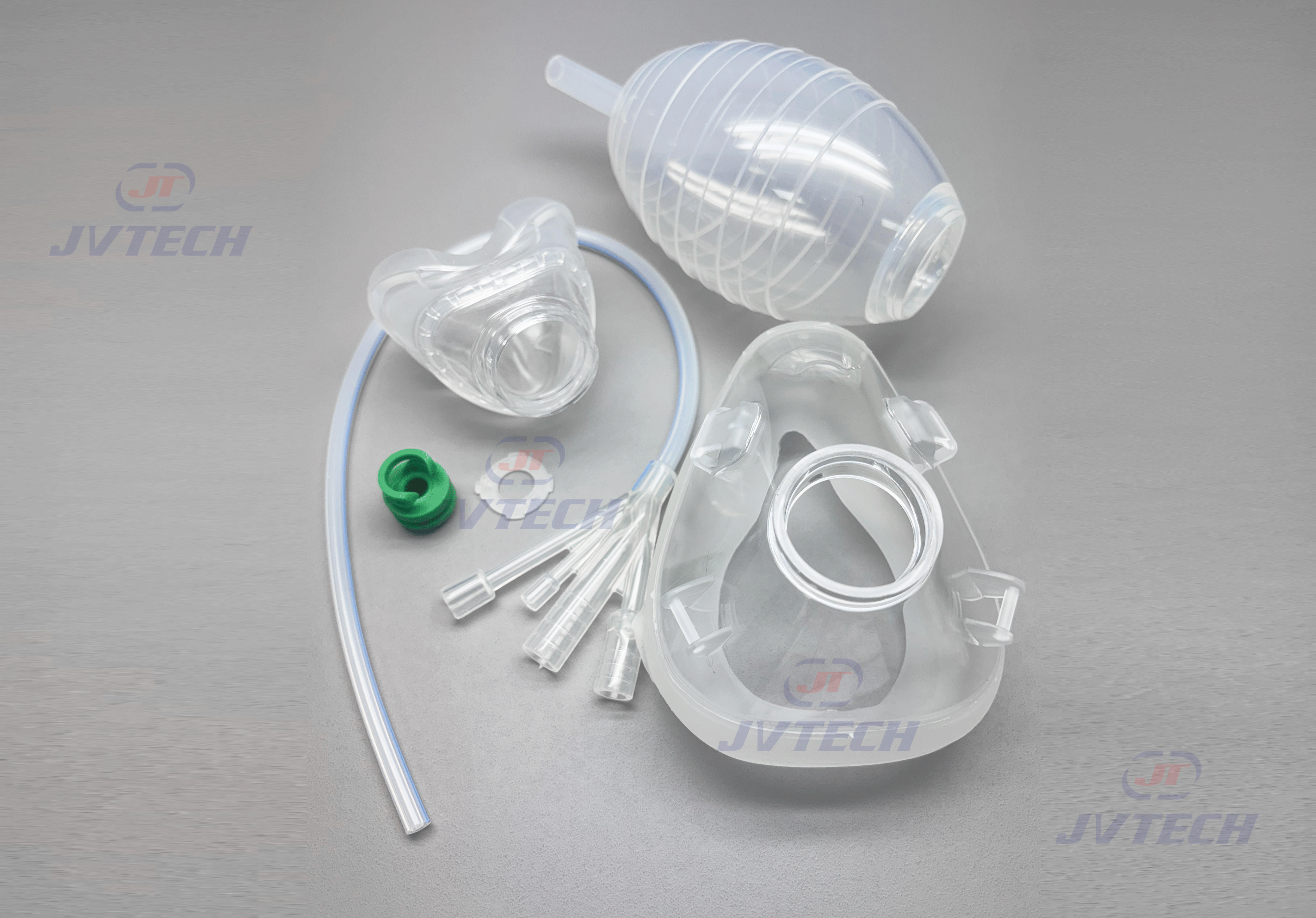

Currently, jvtech has successfully provided customized LSR sealing solutions for multiple leading NEV manufacturers and component suppliers, passing rigorous reliability tests and earning market trust.

四. Jvtech’s Commitment: Delivering Reliability Solutions

Choosing LSR isn’t just selecting a material; it’s embracing a high-standard (process system). At Jvtech, we understand this deeply:

Process Expertise: We possess mature know-how in Liquid Silicone Rubber injection molding, with nano-level control over parameters like temperature, pressure, and time.

Precision Mold Making: Our self-developed high-precision molds are the cornerstone for achieving perfect overmolding and complex seal geometries.

Automated Production Lines: Fully automated production lines ensure consistent quality and reliability for every single part produced.

We understand that in the automotive industry, every tiny seal carries a commitment to safety and quality. Jvtech not only manufactures high-performance LSR components but is also dedicated to providing forward-looking, trustworthy reliability solutions for our customers.