I. Technological Background and Development Status

Liquid Silicone Rubber (LSR) two-shot molding technology involves injecting LSR into a mold under high temperature and pressure to achieve a molecular-level bond with a pre-formed rigid plastic substrate, forming a hard-soft composite structure. The medical industry has extremely high requirements for material safety, sterilization resistance, and mechanical performance. The excellent biocompatibility, sterilization resistance, and mechanical stability of LSR have driven its rapid development in the medical device field.

This technology was initially applied in electronic seals and began to expand gradually from the 1990s. Post-2000, the surge in demand for high-end medical devices such as minimally invasive surgical instruments and implantable devices led to the widespread adoption of LSR two-shot molding due to its advantages. Global medical giants like Medtronic and Johnson & Johnson have adopted it as one of their core processes.

II. Core Application Areas and Technical Advantages

2.1 Surgical Instrument and Tool Manufacturing

LSR two-shot molding can be applied to the surfaces of surgical instrument handles, grips, and seals, providing anti-slip and shock-absorbing properties that align with ergonomic principles. For syringe pistons and valve seals, this process can achieve micron-level precision and long-term sealing stability. Tests show that syringe pistons subjected to over 1000 push-pull cycles maintain more than 95% of their sealing performance.

2.2 Medical Catheters and Interventional Devices

Medical catheters represent one of the most mature application areas for LSR two-shot molding. Modern catheters employ a multi-layer composite structure:

Inner layer: Rigid materials like PA, PEBAX ensure pushability and dimensional stability.

Outer layer: LSR is overmolded to form a soft, biocompatible contact layer.

This structure balances catheter deliverability with tissue protection, reducing the risk of thrombosis and infection.

At catheter hubs and connector sites, LSR overmolding forms sealing rings capable of withstanding high-pressure fluid infusion. Color coding (red for arterial, blue for venous) enables rapid identification. Tests indicate sealing rings maintain performance under pressures of 3 atmospheres.

Example of Medical Catheter Two-Shot Molding Process:

Inject PA substrate and roughen surface (Ra 1.6–3.2 μm)

Rotate mold + control LSR injection temperature via hot runner system at 80–100°C

Maintain holding pressure at 60MPa, cool for 15 seconds

Finished product peel strength ≥3 N/mm, passes 1000 bend tests without delamination

Fully complies with ISO 10555 standards for intravascular catheters.

III. Process Characteristics and Medical Suitability

3.1 Biocompatibility Assurance

Medical-grade LSR passes ISO 10993 series tests, demonstrating no cytotoxicity, sensitization, irritation, or genotoxicity, making it suitable for long-term contact with human tissue. The stable, highly bio-inert siloxane backbone requires no solvents or adhesives during molding, avoiding chemical residues.

3.2 Functional Integration and Structural Optimization

Hard-soft bonding is achieved in a single molding cycle, avoiding contamination and stress concentration associated with adhesive bonding or mechanical fastening. LSR thickness (0.1–5 mm) can be precisely controlled: thinner at bend points for flexibility, thicker at pressure-bearing areas for strength, meeting diverse product functional requirements.

IV. Technical Challenges and Solutions

4.1 Material Interface Bond Strength

The significant surface energy difference between LSR and engineering plastics can lead to delamination. Solutions include:

Plasma treatment to increase substrate surface energy.

Mechanical interlock design (micro-undercuts/serrations).

Use of silane coupling agents to promote chemical bonding.

Achievable bond strength reaches 5 N/mm², meeting medical requirements.

4.2 Post-Sterilization Performance Stability

LSR may harden or discolor under autoclaving. Through formula optimization, vulcanization parameter control, and post-processing, performance variation can be controlled within 5%. Mature products can withstand over 50 autoclave cycles while maintaining usability.

V. Typical Case Analysis

Medical catheter two-shot molding fully demonstrates the advantages of LSR overmolding in catheter structural optimization, sealing performance, and long-term reliability. It complies with ISO standards and is widely adopted clinically.

VI. Jvtech LSR Solution Showcase

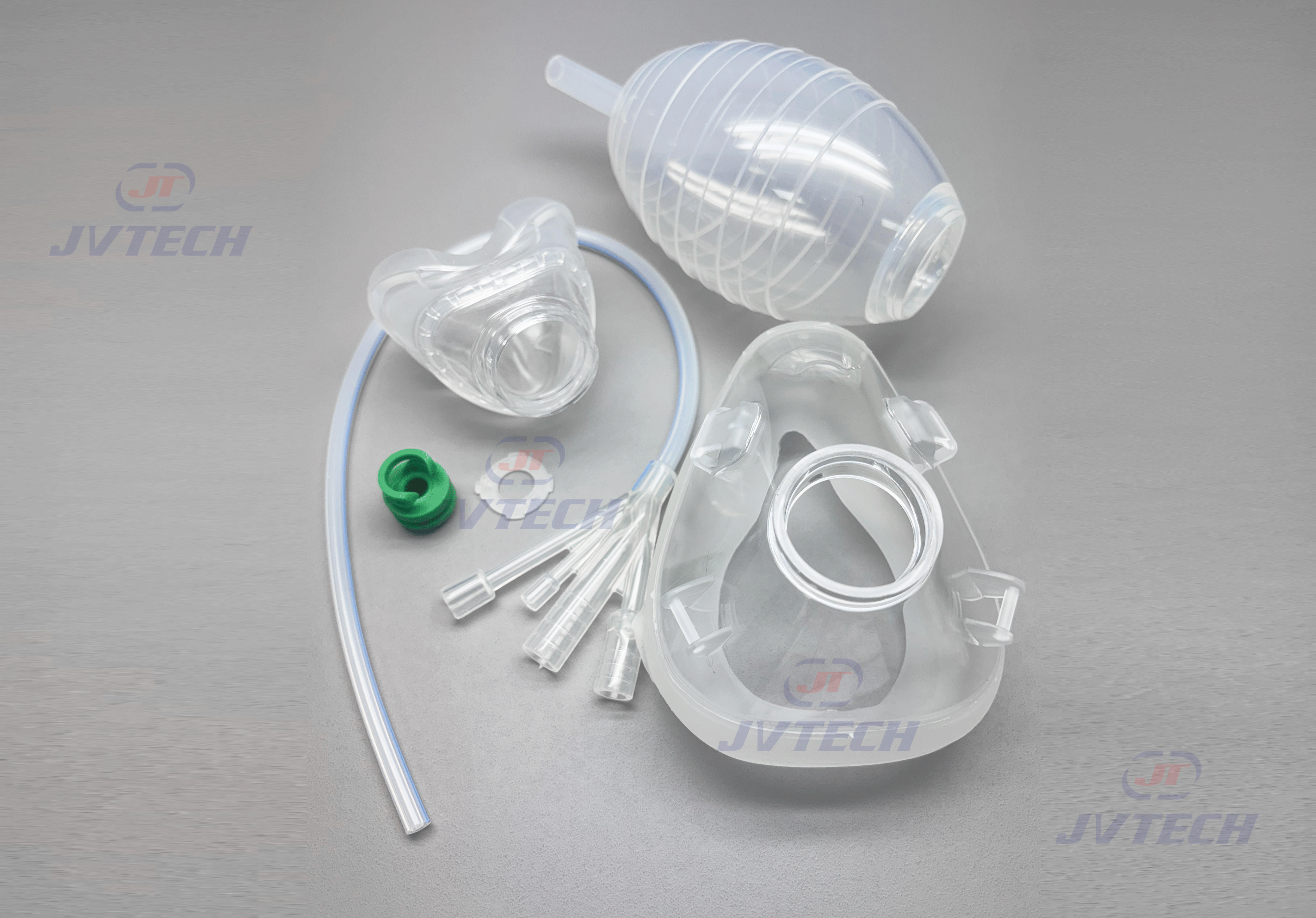

1. Precision Multi-Cavity Design, Safe and Reliable

Medical catheter two-shot molding fully demonstrates the advantages of LSR overmolding in catheter structural optimization, sealing performance, and long-term reliability. It complies with ISO standards and is widely adopted clinically.

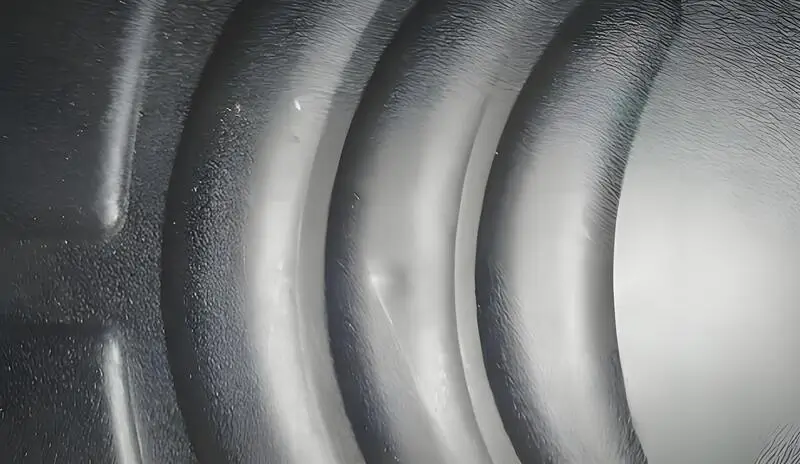

2. Color Coding and Operational Convenience

At catheter hubs and critical connection points, Jvtech utilizes LSR overmolding to form high-precision sealing rings, integrated with a color-coding system for rapid differentiation between arterial, venous, and other functional channels.

As shown in Figure 2, the markings are clear and connections are smooth, enhancing clinical operational efficiency and safety. Whether for high-pressure infusion or complex procedures, Jvtech catheters maintain stable sealing and reliable performance.

3. Complete Kits and Clinical Application

Jvtech provides integrated solutions encompassing catheter bodies, balloons, masks, and accessories. All components utilize medical-grade LSR material, ensuring biocompatibility and sterilization resistance.

The entire medical catheter product line is designed with full consideration for functional integration and structural optimization, providing high-performance, ready-to-use medical device kits for surgery and clinical care. Each product undergoes strict quality control, complying with international standards such as ISO 10555.