Transparency ≠ Fragility. How does optical-grade silicone achieve such high clarity?

This article unveils the “invisible material” behind applications such as condenser lenses and secondary optics—optical-grade liquid silicone rubber (LSR).

Optical-grade Liquid Silicone Rubber (LLSR, Light Liquid Silicone Rubber) is a highly transparent liquid silicone elastomer distinguished by exceptional light-transmission performance. It not only offers extremely high clarity (with transmittance reaching up to 95%) but also delivers outstanding resistance to ultraviolet and blue-light degradation, along with excellent processability.

Typical Process:

The material consists of A and B components, which are mixed at a 1:1 ratio through a static mixer, then injected into a mold for heat curing (compression molding is also applicable).

一、Key Performance Data

Showcasing its “transparent” power with data — here are five invisible characteristics that turn sci-fi into reality:

Excellent transparency: Light transmittance reaching 92–95%

High tensile strength and tear resistance

Outstanding resilience

Exceptional thermal stability and weather resistance: Operating temperature range -60°C to 250°C

Anti-yellowing and superior heat-aging resistance

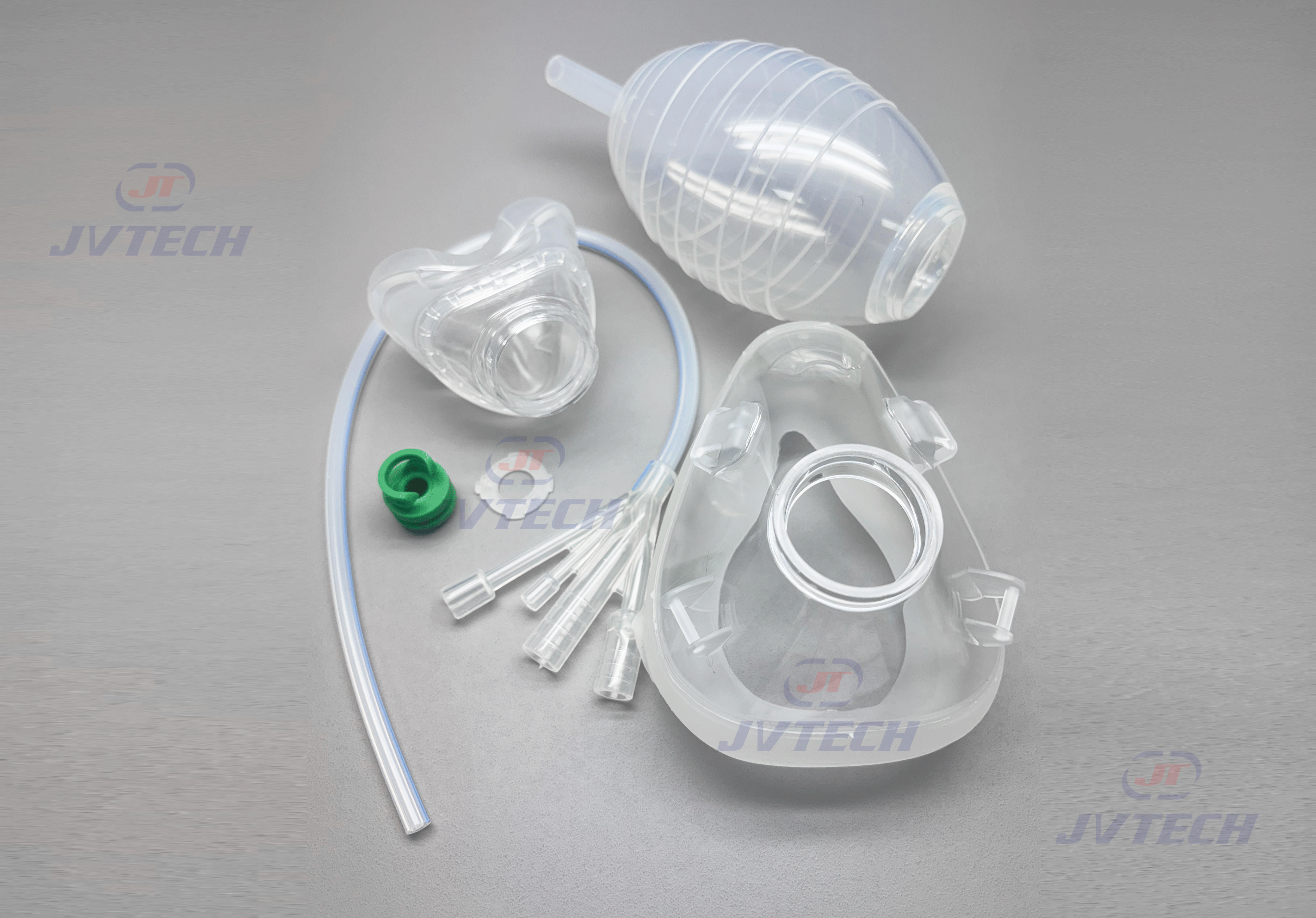

二、Typical Application Scenarios:

Automotive light covers

Secondary optical components

Eyeglass nose pads, diving masks, and sports goggles

三. Analysis of Technical Challenges

(一) Why is achieving a 99% yield difficult?

The main factors affecting yield include: raw material impurities, curing bubbles, and whitening during application.

Raw Material Impurities

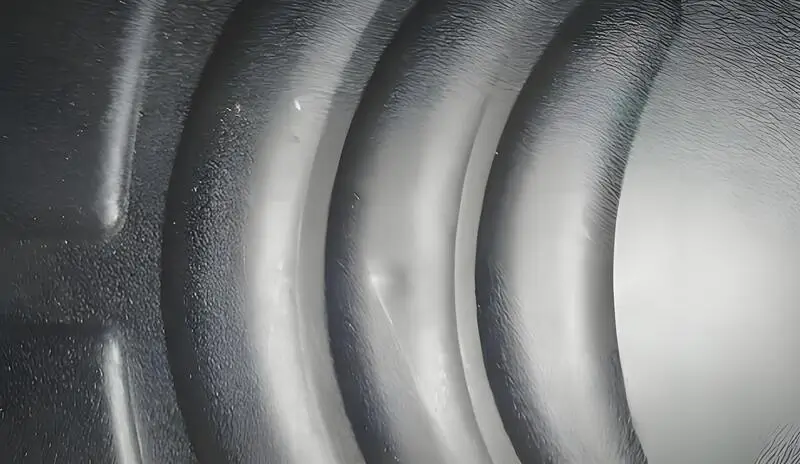

(二) Detailed Analysis of Curing Bubbles

1. Common Forms:

-

Micro bubble clusters: Dense, needle-like bubbles inside or on the surface, appearing as cloudy defects.

-

Isolated large bubbles: Single, noticeable bubbles (diameter may exceed 0.1 mm) with smooth edges.

-

Surface-dented bubbles: Ring-shaped pits left after bubble rupture.

2. Typical Causes:

-

Incomplete vacuuming or overly rapid curing during the curing process.

-

Air entrapment during A and B component mixing, insufficient degassing.

-

Mold surface contamination (e.g., dust) causing bubble adhesion.

(三) Application Challenges

Whitening: Mainly related to the silicone resin raw material, especially the hydroxyl content.

Bluing: Product bluing is partially associated with the raw materials used; some occurrences have been reported.

Weather resistance and yellowing: Long-term weather exposure or high-temperature yellowing remains a key challenge. Domestic products may still lag in meeting such specialized requirements, particularly in terms of stability. The primary reason is the purity of the silicone resin, with residual impurities from the synthesis process being a significant factor.

四、 Innovative Application Cases

In the field of precision optics, material purity and molding processes directly determine the final product’s performance and yield. We have developed and supplied in bulk high-transmittance condenser lenses for smart products of several globally renowned home appliance brands.

Each lens must meet key specifications, including over 93% light transmittance, excellent optical uniformity, and long-term resistance to yellowing. By utilizing our self-developed high-purity optical silicone raw materials and precisely controlling the injection molding process, we have achieved lenses free of internal bubbles, impurities, or cloud-like defects, fully satisfying the stringent standards for uniform light convergence.

五、 Seeking Reliable Material and Process Solutions

The performance of optical-grade liquid silicone rubber highly depends on material purity and process stability. Jvtech Silicone focuses on providing high-purity optical-grade LSR materials along with molding process support, aiming to help customers address application challenges such as yellowing, whitening, and bubbles from the source, thereby improving product yield.