In the silicone products industry, we are well aware that 70% of a product’s performance, consistency, and safety are determined by its raw materials. Incoming inspection is not only the first checkpoint in quality control, but also a core link that shields customers from upstream risks, ensures smooth manufacturing, and guarantees the reliability of end products.

一、Control System: Triple Protection, Proactive Defense

The “Supplier-Data-Application” triple protection system intercepts problems outside the production line.

First Layer: Supplier Collaborative Protection

Proactively manage the source. Through strict supplier access audits, regular performance evaluations, and data sharing, quality assurance is established at the source through supplier audits, qualification verification, and performance evaluations before raw materials arrive.

Second Layer: Data-driven Inspection Protection

Reject “relying on feelings”; everything is based on data. By relying on characteristic testing equipment and standard methods specified in material property sheets, each batch of incoming materials undergoes quantitative evaluation to ensure the objectivity and scientificity of the judgment.

Third Layer: Application Scenario Linkage Protection

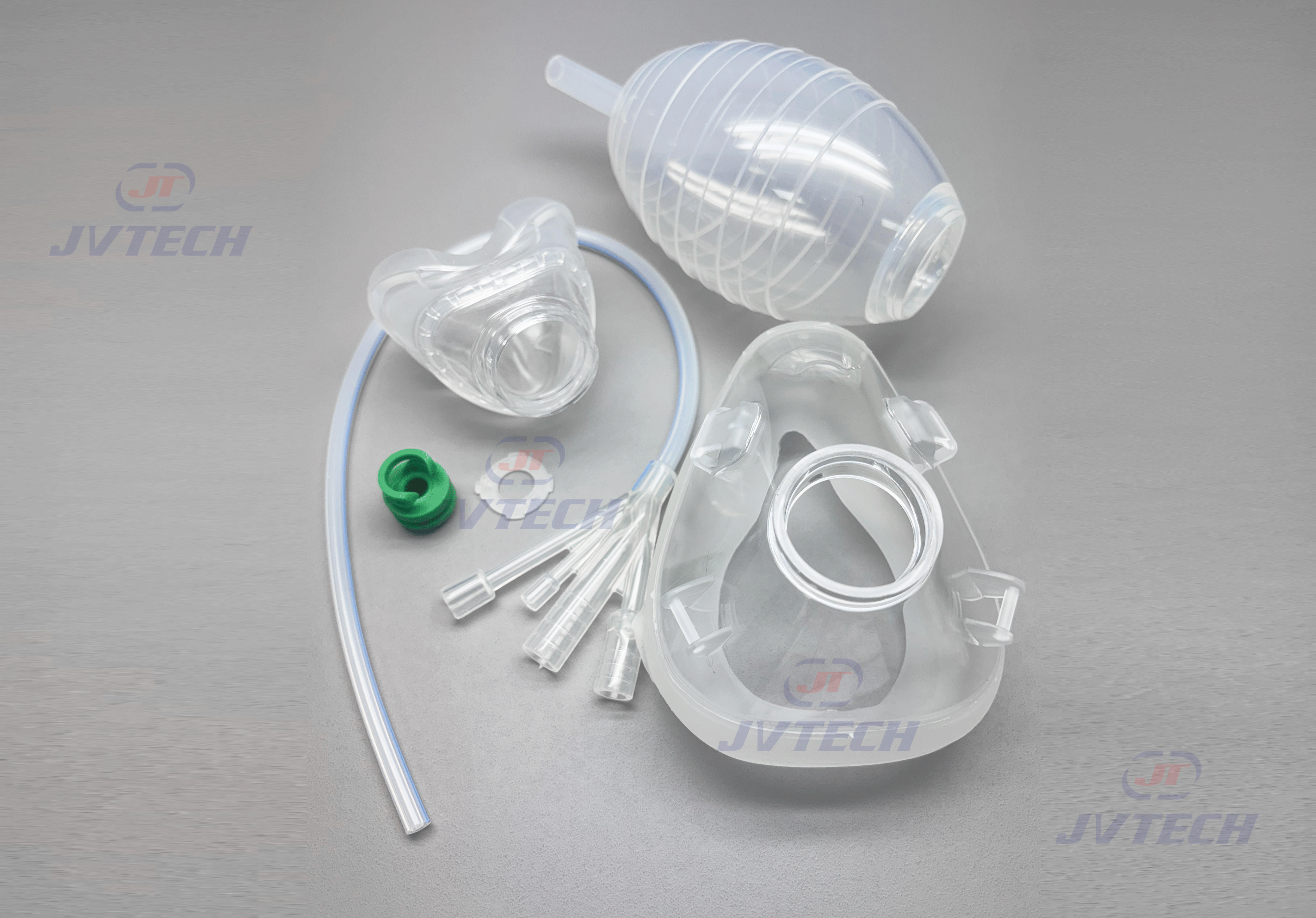

Inspection standards dynamically adapt to your product requirements. For medical supplies, we strictly control biocompatibility documents; for high-transparency products, we tighten appearance inspection; for dynamic seals, we focus on long-term durability. Your application scenario is our inspection standard.

二、Implementation Standards: Key Dimensions and Data Verification

The following are the core inspection dimensions for liquid silicone rubber (LSR) raw materials:

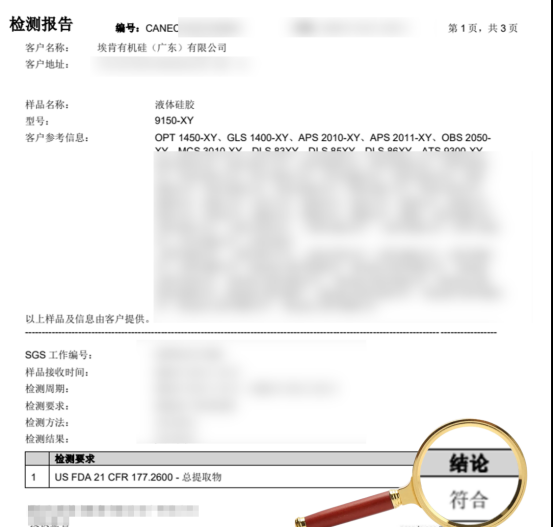

1.Identity Verification and Document Review

Check: material brand, model, batch number, and production date to ensure full traceability.

Review: For each batch of “Third-Party Test Reports” provided by suppliers, mandatory verification of compliance with regulations such as RoHS, REACH, and FDA is conducted.

2.Key Performance Data Testing

Physical and Mechanical Properties

Hardness: A high-precision Shore durometer is used, with multi-point measurements to ensure stability within and between batches.

Tear strength & Tensile strength: Standard test pieces are tested by a universal tensile testing machine, and the data must fall within the preset specification range.

Viscosity: Monitor the viscosity value to ensure stable flow performance and prevent defects such as material shortage or flash in your production process.

3.Appearance and Packaging

Check the tightness of the packaging to prevent contamination.

Visually inspect that the raw materials have a uniform color, no impurities, and no agglomeration.

三、Continuous Improvement: Closed-Loop Management from

Inspection to Optimization

Inspection is not the end, but the starting point for continuous improvement.

Standardized Process: Follow the standardized process of “inspection application – sampling – testing – judgment – disposal – filing” to ensure that every step is traceable.

Non-conforming Product Control: Once non-conforming products are found, isolation and identification shall be initiated immediately, and strict return / replacement procedures shall be implemented. Meanwhile, a “Corrective Action Report” shall be issued to the supplier, requiring them to conduct a root cause analysis and rectify the issue within a specified time limit.

Data-Driven Decision-Making: All inspection data is entered into the system and analyzed. Regularly generate supplier quality reports, which serve as the core basis for optimizing the supply chain and drive a spiral improvement in quality.

Quality Control FAQ

Q1: When inspection resources are limited, how to determine the priority of inspections?

Implement a risk-classified inspection strategy. All incoming materials must pass the baseline of identity verification and document review. On this basis, for new suppliers or new products, a full-item inspection shall be initiated. For suppliers with stable cooperation, based on their historical quality performance, high-frequency monitoring will be focused on high-risk items such as hardness, viscosity, and appearance, while periodic inspections will be conducted on other items, so as to achieve optimal resource allocation.

Q2: When an unqualified batch is found, apart from returning the goods, how to fundamentally solve the problem?

Returning the goods is just the first step. The key lies in initiating root cause analysis and a closed-loop for improvement. We will immediately issue a Corrective Action Report (CAR) to the supplier, requiring them to provide a detailed root cause analysis and measures to prevent recurrence, and will track and verify the effectiveness of their improvements. This turns a one-time quality issue into an opportunity to enhance supply chain capabilities.

Q3: How do the inspection standards address the special requirements of your company’s products?

This is precisely the core of our “application scenario-linked protection”. In the early stage of project initiation, we will fully communicate with you regarding the product’s final usage environment, service life requirements, and regulatory thresholds. Based on this, in addition to the standard inspection items, we will customize exclusive additional test items or more stringent acceptance criteria for you to ensure that the incoming materials perfectly match your product requirements.

Conclusion

At Jvtech, every batch of silicone raw materials undergoes strict inspection and verification. We control quality through data, records and standards, ensuring that every product delivered to customers can stand up to inspection and is worthy of trust.

If you are looking for a reliable liquid silicone partner, please contact us. Jvtech will provide you with professional support.