一、 What Is Liquid Silicone Rubber (LSR) Insert Overmolding?

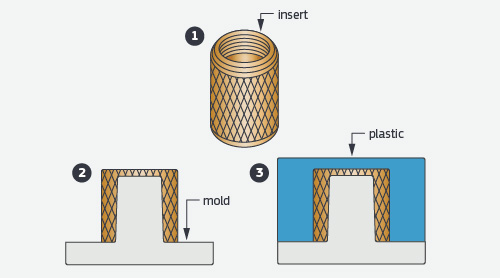

Liquid Silicone Rubber (LSR) insert overmolding is a specialized branch of the overmolding process. The procedure involves placing a pre-formed insert—typically a non-plastic component such as metal, ceramic, specific types of plastic, or electronic elements—into the mold cavity before the liquid silicone is injected, cross-linked, and cured.

During the process, the liquid silicone encapsulates the insert and bonds to it—either chemically or through mechanical interlocking—thereby creating a hybrid multi-material component that combines both softness and rigidity in a single manufacturing step.

Unlike standard overmolding — which typically involves plastic-on-plastic combinations — liquid silicone rubber (LSR) insert overmolding integrates materials with vastly different properties, such as metal + LSR or plastic + LSR. This fusion endows the final component with enhanced sealing performance, electrical insulation, biocompatibility, heat resistance, and a comfortable tactile feel.

It is especially well-suited for embedding rigid structural parts or functional elements — such as connectors, sealing plates, circuits, or sensors — directly into a soft silicone body, achieving structural integrity and multifunctionality in a single process.

二. Process Steps

1、Insert Preparation

The inserts (such as PC brackets, PEEK components, or metal terminals) are cleaned, then treated with plasma or primer coating to enhance adhesion, followed by a thorough inspection to ensure surface quality and dimensional accuracy.

2、 Mold Loading

Using robotic automation with vision guidance, the inserts are precisely positioned into the mold cavities to ensure alignment and consistency during molding.

3、 Mold Clamping

The mold is closed and maintained under precise temperature control (usually heated to initiate LSR curing).

4、LSR Injection

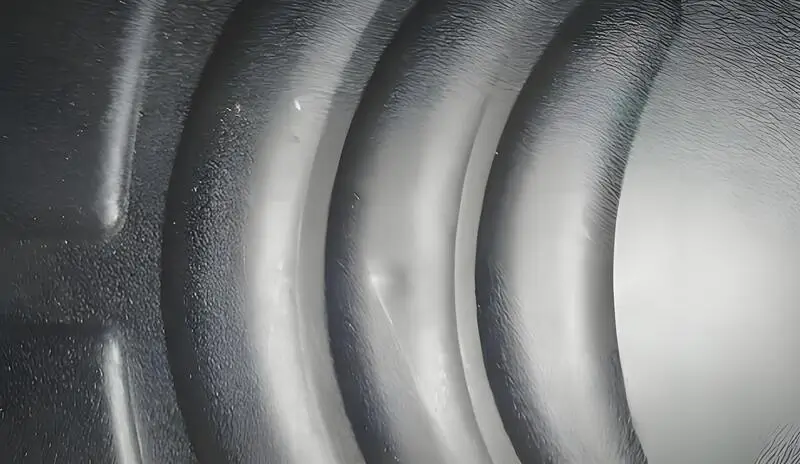

Under relatively low pressure, the two-component liquid silicone rubber (LSR) is injected around the insert. Inside the mold, the silicone undergoes a thermal cross-linking reaction, forming a seamless bond with the insert.

5、 Curing

With the mold kept at curing temperature, the liquid silicone vulcanizes into an elastomer over a set period, creating a strong and permanent bond with the insert.

6、 Ejection

Once cured, the molded part is ejected from the mold. The insert is now encapsulated within the soft, elastic silicone structure.

7、 Quality Inspection

Each part is inspected for bond integrity, absence of flash, and precise insert positioning, ensuring consistent quality and performance.

三、 Material Combinations and Bonding Mechanisms

Successful insert overmolding depends on material compatibility, ensuring that the components do not crack, delaminate, or detach after molding. The table below summarizes common insert–LSR pairings and their key bonding mechanisms:

| Insert Type | Typical LSR Type Used | Key Bonding Mechanism |

|---|---|---|

| PC / ABS / PC-ABS | High-, medium-, or low-hardness LSR | Primer promotes chemical bonding |

| PEEK / Nylon | Food-grade or medical-grade LSR | Surface micro-etching + primer coating |

| Metals (Stainless Steel, Aluminum) | High-tear-strength LSR | Primer or plasma treatment for chemical adhesion |

| Ceramic Inserts | High-temperature-resistant LSR | Mechanical interlocking + primer |

| PCB Boards / Sensors | Conductive or insulating LSR | Specialized primers enable sealing and protective encapsulation |

These material pairings and surface treatments ensure durable, high-precision integration of rigid and elastic components—critical for applications that demand reliability, insulation, or hermetic sealing.

四、 Advantages and Challenges

| Advantages | Challenges |

|---|---|

| Excellent sealing and insulation performance | Surface pretreatment (primer or plasma) is critical for reliable bonding |

| Wide temperature resistance range (-50°C to +200°C or higher) | Requires precise control of mold temperature and LSR mixing ratio |

| Outstanding biocompatibility and chemical stability | Preventing LSR flash demands extremely high mold manufacturing precision |

| Soft touch and superior shock absorption | High initial investment in molds and equipment |

| Integration of complex soft–hard structures in a single step | Material cost of LSR is typically higher than that of common thermoplastics |

This table summarizes how LSR insert overmolding offers remarkable functional and sensory benefits, while also posing technical and economic challenges that require advanced process control and precise engineering to overcome.

五、 Industries Using Overmolding Technology

| Industry | Typical Applications |

|---|---|

| Automotive | Sealed connectors, sensor protective covers |

| Electronics | Keypad mats, connector seals |

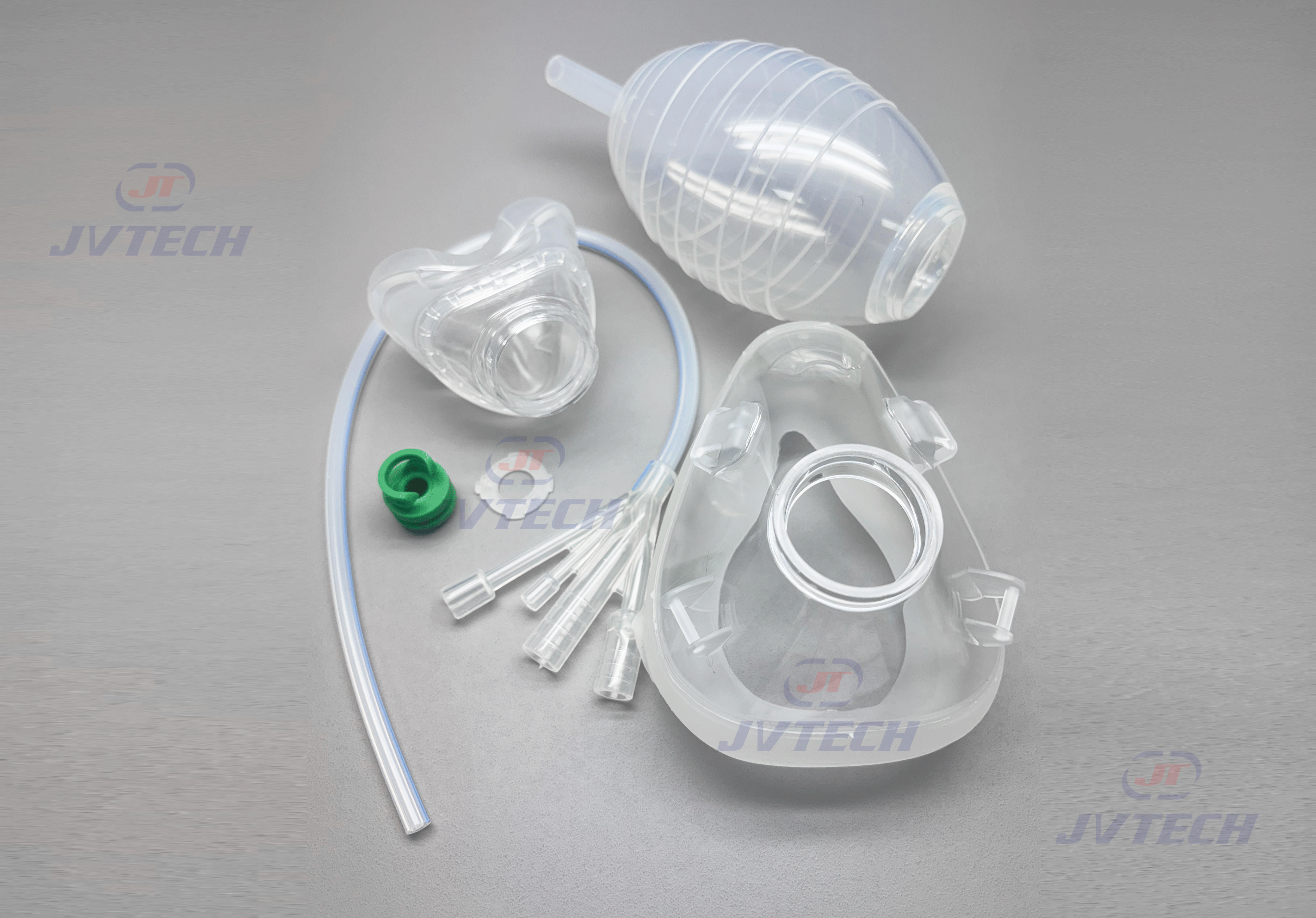

| Medical | Breathing masks, valve assemblies, surgical instrument handles |

| Infant & Baby Products | Pacifiers, toothbrush handles |

| Home Appliances | Rice cooker sealing rings, coffee machine components |

| Aerospace | High and low temperature–resistant seals |

| Consumer Goods | Waterproof switches, wearable device bands |

Liquid silicone insert overmolding is now widely adopted across these industries due to its ability to deliver seamless integration, reliable sealing, and user comfort, while meeting strict safety and performance standards.

六. Application Examples

Smartwatch / Fitness Band:

The PC watch case serves as an insert overmolded with LSR straps, achieving seamless one-piece molding, skin-friendly comfort, and excellent waterproof performance.

Automotive Ignition Coil:

A PBT housing is overmolded with high-voltage conductive LSR, creating a permanent seal that prevents corona discharge and significantly enhances voltage resistance.

Medical Valve:

A polyester frame is completely encapsulated with medical-grade LSR, ensuring biocompatibility, flexibility, and long-term durability for continuous medical use.

Insert overmolding is gaining greater importance in automotive, electronics, medical, and consumer product sectors. From precision engineering to functional performance and material optimization, every stage of the process tests a manufacturer’s technical expertise and process discipline.

At Jvtech Silicone, we are dedicated to delivering customized LSR component development, rapid mold prototyping, and high-volume precision molding solutions. Our goal is to help clients achieve a seamless, efficient, and integrated workflow — from design to production — ensuring that every insert-molded component is accurate, stable, and reliable.