Did you know that two-color injection molding technology is widely used in our daily lives? It is commonly found in various products such as two-color toothbrushes, wires, automotive components, and more. If you want to enhance your product’s competitiveness in the market, understanding the advantages of two-color injection molding is crucial. This technology not only improves product appearance and performance but also optimizes production processes, reduces manufacturing costs, and minimizes waste. Let’s explore how two-color injection molding can deliver a better user experience!

What is Two-Color Injection Molding?

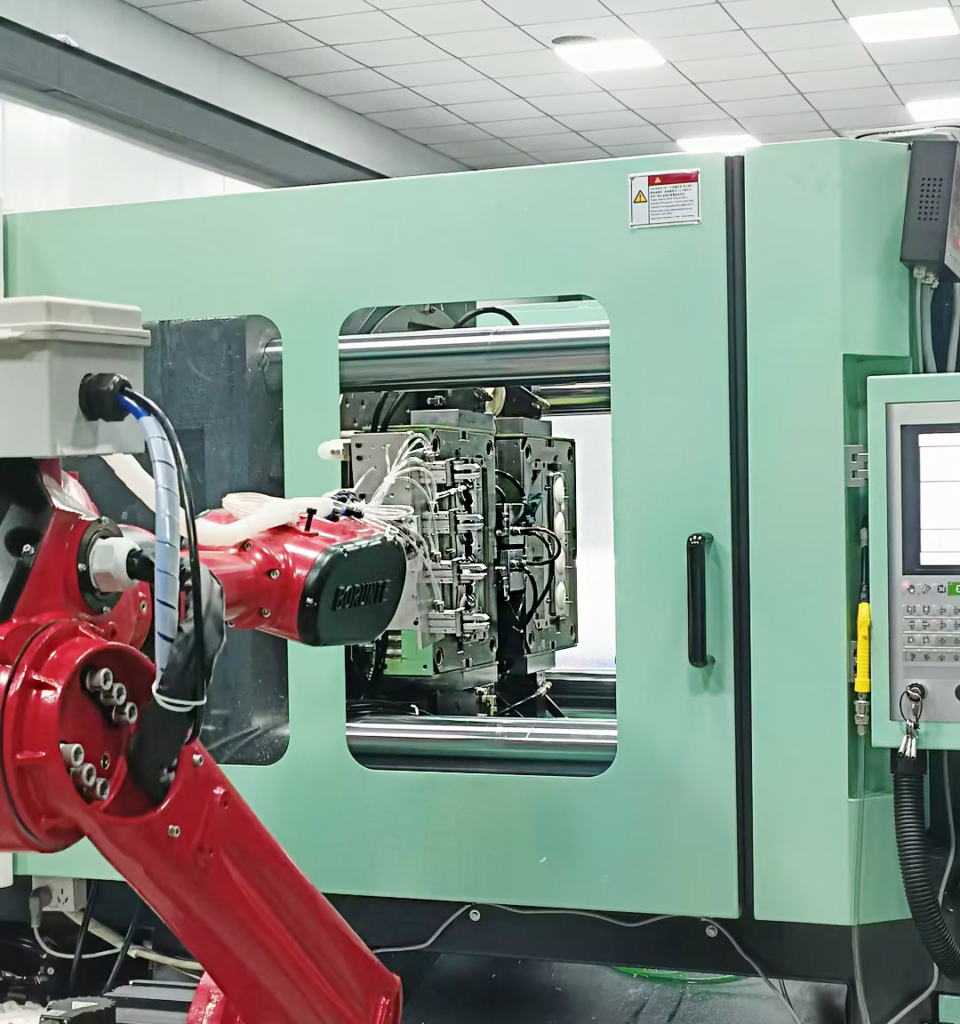

Two-color injection molding (Double Injection Molding), also known as two-material injection molding or two-color shooting, is an advanced technique in injection molding processes. The basic principle involves feeding two different plastic materials into the injection system of the same injection molding machine. Through simultaneous or alternate injection into the mold, products with two different colors or materials are formed.

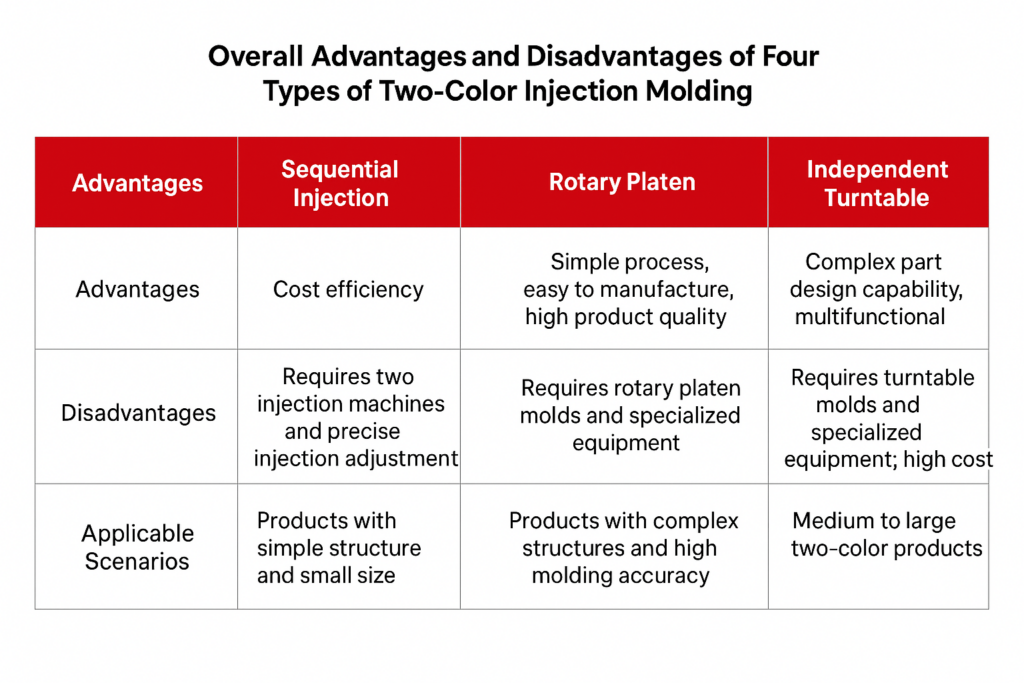

Two-color injection molding typically requires special mold structures, such as moving plates or rotating plate systems, to ensure precise control of the injection position and timing of the materials. The production mechanisms may vary slightly depending on the specific technology type. Below, we introduce four mainstream two-color injection molding technologies:

Sequential Injection Technology

The basic process of sequential injection technology involves first injecting the first material into the mold cavity. After partial curing, the second material is injected to form the final composite component. The two materials are injected sequentially according to a set order to ensure bonding strength and functional realization.

Advantages Analysis

Sequential injection technology offers three significant advantages:

High Design Flexibility: By precisely controlling the position of different materials, more complex structural designs can be achieved, such as presenting different colors, textures, or material properties in specific areas, greatly enhancing product aesthetics and practicality.

Excellent Bonding Effect: Injecting the second material after the first has partially cured ensures a tighter bond and higher interface strength, resulting in a more robust and durable product structure.

Strong Material Compatibility: Supports the combination of materials with different properties, especially suitable for cases where melting points or chemical compositions differ significantly, providing more possibilities for enhancing overall component performance.

Application Scenarios

Sequential injection technology is particularly suitable for the following situations:

Products requiring multi-color effects

Large-batch, short-cycle production of two-color injection products

Components requiring high bonding strength

Rotating Plate Technology

Rotating plate technology utilizes a rotating plate system. After the first injection, the mold rotates, allowing the second material to be injected on the other side, efficiently completing the manufacturing of two-color or two-material components.

Technical Advantages

Significantly Improved Production Efficiency: Enables simultaneous injection of two materials, greatly shortening the molding cycle and improving equipment utilization.

High Alignment Accuracy: Mold rotation ensures accurate and consistent positioning for the second injection, avoiding product deviations or defects.

Simplified Mold Structure: Utilizes a double-cavity mold design, reducing manufacturing complexity and cost while extending mold service life.

Application Fields

This technology is widely used in:

Structurally complex automotive interior parts, industrial components, household appliance parts, etc.

Products with high requirements for appearance and surface quality, such as electronic device housings

Two-color products requiring high-precision fit

Core Back Technology

Core Back technology involves setting movable cores in the mold. The first material is injected around the core, which then retracts to create a cavity. The second material is injected into this cavity to achieve overmolding, providing more design possibilities for products.

Technical Characteristics

Excellent Overmolding Performance: Achieves perfect combination of hard and soft materials, significantly improving product grip, cushioning performance, and sealing effect.

Broad Design Space: Supports complex shapes and diverse material combinations, enhancing product individuality and functionality.

Significant Performance Optimization: Flexible material selection based on component needs greatly improves wear resistance, insulation, chemical resistance, and other characteristics.

Suitable Applications

Core Back technology is particularly suitable for:

Small and medium-batch production or high-value-added products

Products with strict requirements for appearance accuracy, color, and texture

Products requiring special protection or functional zones

Spin Stack Technology

Spin Stack technology employs an advanced rotating stack mold module. The first material is injected, then the mold rotates, and the second material is injected to perfectly achieve the molding of complex components with multiple materials and colors.

Technical Advantages

Realization of Complex Structures: Precise positioning of multiple materials supports

Diverse Material Combinations: Integrates materials with different properties such as rigidity and flexibility, transparency and opacity.

Improved Production Efficiency: Single molding process reduces assembly steps, optimizes production, and reduces costs.

Application Range

This technology is mainly used for:

Production of large two-color plastic parts

Products with special shapes, such as those with concave-convex structures

Complex multi-material components such as plastic gears and nuts

The Five Core Advantages of Two-Color Injection Molding

Two-color injection molding technology significantly enhances product competitiveness, specifically in the following five aspects:

1. Greatly Expanded Design Possibilities

A single molding process can achieve complex patterns, multiple colors, and multi-material combinations without post-production splicing or processing, providing designers with greater creative space.

2. Significantly Enhanced Product Functionality

By integrating the characteristics of multiple materials, such as a hard base paired with a soft grip, not only is the ergonomic design optimized, but the user experience is also greatly improved.

3. Improved Cost and Time Efficiency

Reducing assembly steps saves labor, inventory, and equipment investment, optimizes production processes, and significantly improves overall efficiency.

4. Increased Product Durability

The complementary effect between materials enhances the overall strength of the part, extends product service life, and improves product quality reliability.

5. Significant Environmental Protection and Waste Reduction

Maximizes material utilization, supports the use of renewable materials, promotes the implementation of green manufacturing concepts, and reduces environmental burden.

In summary, two-color injection molding technology effectively expands product design boundaries, enhances functional performance, improves production efficiency and product durability, while reducing environmental impact. Rational use of this technology can significantly enhance product market competitiveness.

Typical Application Fields of Two-Color Injection Molding

Two-color injection technology is widely used across industries to efficiently produce high-quality composite material products. The following are the main application areas:

Household Appliance Manufacturing

Widely used in kitchen appliances, vacuum cleaning equipment, personal care products, etc., significantly improving product appearance, aesthetics, and grip comfort, enhancing market competitiveness.

Consumer Electronics

Applied in mobile phone housings, remote controls, keyboards, and game controllers, achieving diverse designs such as hard-soft combinations and transparent-opaque areas to meet personalized needs.

Automotive Manufacturing

Widely used in interior parts, buttons, handles, dashboards, etc., improving visual appeal and practical functionality to meet the high standards of the automotive industry.

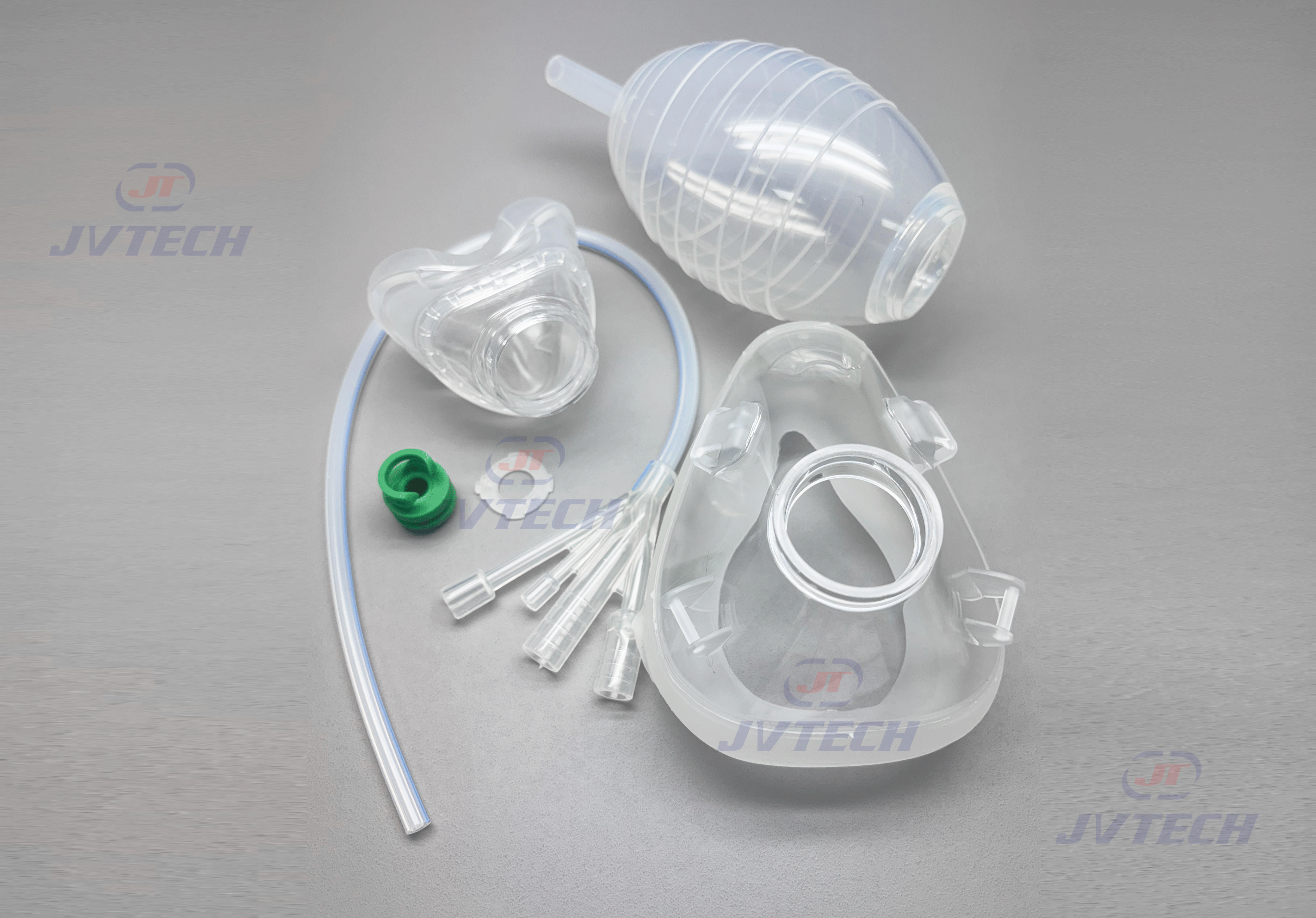

Medical Device Field

Focuses on manufacturing medical components with features such as antibacterial surfaces, soft-touch handles, or transparent viewing windows, meeting the dual requirements of functionality and safety for medical devices.

Zhongshan Jvtech Silicone Technology Co., Ltd. —— Your Reliable Two-Color Injection Molding Partner

Two-color injection molding technology already holds a vital position in modern manufacturing. Zhongshan Jvtech Silicone Technology Co., Ltd. is committed to providing professional two-color injection molding solutions. The factory has fully obtained ISO 9001, ISO 14001, ISO 13485, and ISO 45001 management system certifications.

From mold development to mass production and delivery, we adhere to standardized quality management and are equipped with advanced instruments for product development and quality verification. Our technical team has extensive industry experience and can provide customers with full-process services from design consultation to production manufacturing.

No matter which industry you are from, Jvtech Technology is willing to provide you with competitive product solutions using reliable and efficient two-color injection molding technology. We focus on long-term cooperation with customers, ensuring that each project receives the best technical support and after-sales service.

Please feel free to contact us through the official website or phone number for more product information and cooperation opportunities. Our professional team is always ready to provide technical consultation and solutions to create high-quality products together.