Medical-grade liquid silicone rubber is highly favored in the manufacture of medical devices due to its excellent biocompatibility and chemical inertness. Its chemical inertness means it is unlikely to react with other substances, particularly exhibiting strong resistance to oxidation, which ensures the long-term safety of medical devices and implants. In addition, its outstanding chemical and thermal resistance distinctly sets it apart from elastomeric materials commonly used in industrial applications, such as conventional rubber.

一、Biocompatibility: Safe for Interaction with the Human Body

Biocompatibility refers to a material’s ability to safely interact with living tissues without causing adverse reactions. Medical materials, once introduced into the human body, should not trigger toxicity, rejection, or other harmful responses.

Liquid silicone rubber (LSR), thanks to its chemically stable composition and rigorous manufacturing processes, inherently possesses excellent biocompatibility, making it particularly suitable for medical devices that require direct or indirect contact with human tissues.

FDA Certification: Compliance and Safety Assurance

Owing to its outstanding biocompatibility, medical-grade liquid silicone rubber has received approval from the U.S. Food and Drug Administration (FDA), making it suitable not only for the manufacture of medical devices but also for certain pharmaceutical packaging applications.

LSR features an exceptionally wide operating temperature range (approximately -50°C to 200°C) and remains flexible without becoming brittle even in low-temperature environments, making it highly suitable for implants and applications involving fluctuating high and low temperatures. All FDA-approved silicone materials must comply with relevant federal regulations to ensure their safety and reliability.

二、LSR Molding Process: The Key to Precision Manufacturing

The manufacturing of medical devices demands extremely high process precision, as even minor defects can compromise the safety and effectiveness of the instruments. The liquid silicone rubber (LSR) molding process serves as the key to achieving these rigorous standards:

Precision Molding: Exact Dimensions Every Time

Liquid silicone rubber molding utilizes high-precision molds and injection molding technology, combined with biocompatible silicone materials, to produce medical device components with complex structures and exact dimensions. Design-for-Manufacturing (DFM) principles, along with simulation tools such as Moldflow® and SIGMASOFT®, enable engineers to optimize mold designs and processing parameters in a virtual environment, ensuring precise control over critical production factors like temperature and venting.

Defect Comparison: Traditional Rubber Processes vs. LSR Precision Injection Molding

Compared with traditional rubber molding or extrusion processes, liquid silicone rubber (LSR) injection molding offers clear advantages in process precision and consistency. Traditional rubber medical products often rely heavily on manual expertise and post-processing. With wider process windows and numerous variables, product quality is easily affected by factors such as formulation, curing time, and operator differences.

Traditional Rubber Defects vs. Liquid Silicone Rubber Quality

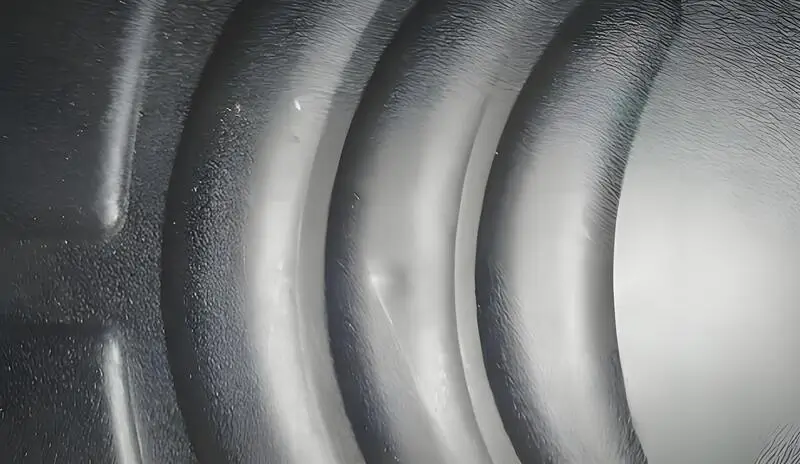

In terms of dimensional control, traditional rubber products often exhibit significant tolerance fluctuations and poor batch-to-batch consistency. This is especially pronounced in complex structures or thin-walled areas, where deformation and dimensional deviations are more likely to occur. While such issues might be acceptable in ordinary medical consumables, they often pose serious risks in implant-grade or high-precision medical devices.

Deformation and Uneven Thickness in Traditional Rubber Products

In contrast, LSR injection molding achieves higher dimensional consistency and repeatability through closed automatic metering and mixing, precision molds, and stable processing parameters. Precise control of temperature, pressure, and venting during molding ensures that products meet design specifications immediately upon demolding, significantly reducing the need for post-processing and manual intervention.

Efficient Production: Accelerating Time-to-Market

The LSR molding process is highly automated, reducing reliance on manual labor and improving production efficiency. Cold-runner technology minimizes material waste, saving costs. LSR also cures rapidly and requires no post-baking, further shortening the production cycle.

In industries like medical devices, where rapid iteration is critical, LSR molding technology effectively helps companies shorten product development cycles and respond quickly to market demands.

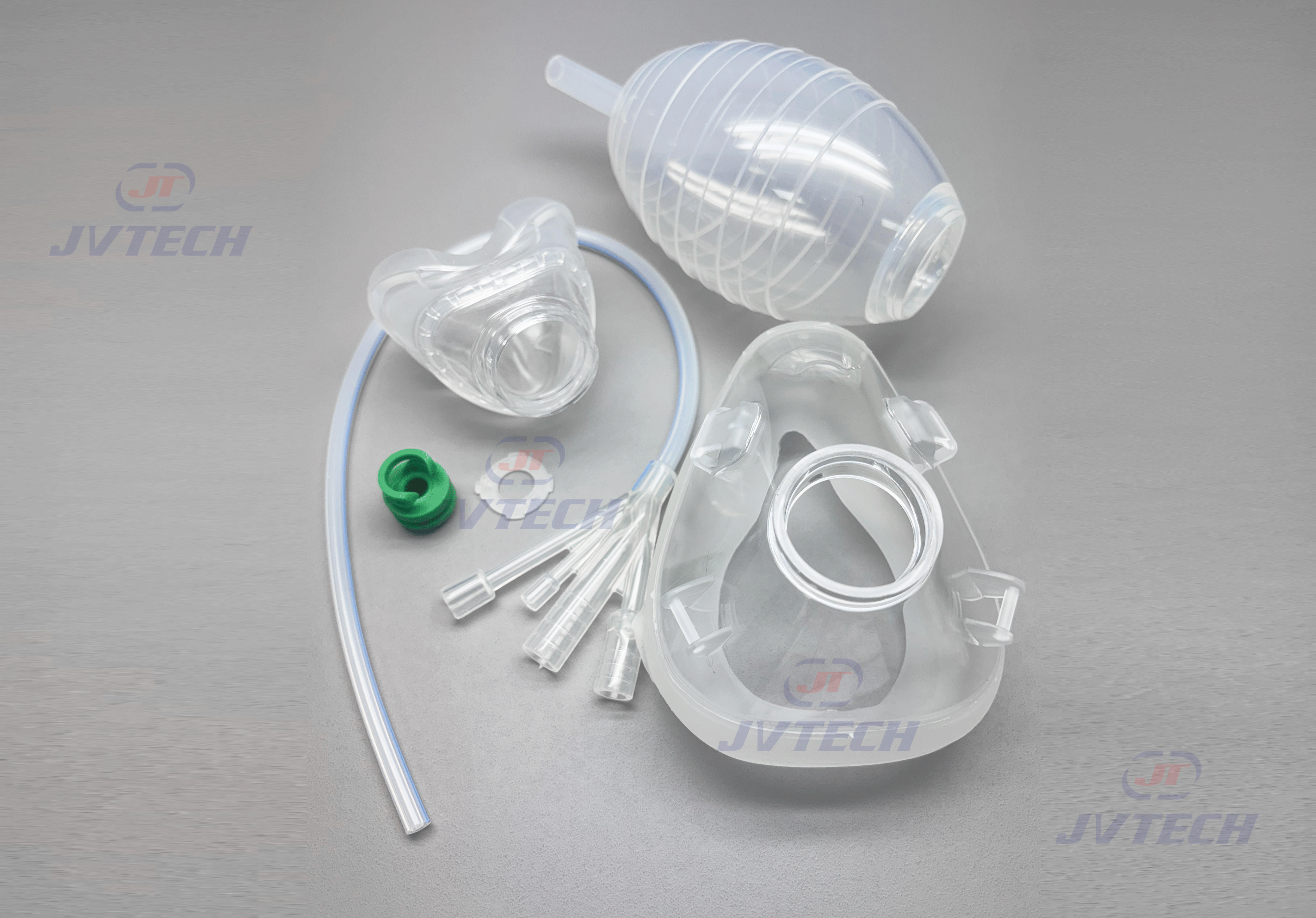

三、Practical Applications of Medical-Grade LSR

In the global medical device industry, liquid silicone rubber (LSR) has long been the core material choice for many established brands.

Respiratory therapy products, such as ResMed masks, involve prolonged, direct contact with patients’ faces, demanding exceptionally high standards for material softness, sealing performance, biocompatibility, and long-term stability.

Similar applications also include:

Masks and sealing gaskets in respiratory and anesthesia systems

Medical catheters, valve membranes, and other components in prolonged contact with human tissues

Medical consumables that require repeated cleaning, disinfection, or even high-temperature sterilization

Although these products vary in form, their core material requirements are highly consistent: stability, safety, repeatability, and suitability for scalable production.

It is against this industry backdrop that Jvtech Silicone continues to focus on medical-grade liquid silicone rubber materials and precision molding processes.

We pay attention not only to the inherent performance of the materials but also to their molding consistency, batch stability, and regulatory compliance in real medical products. From early-stage material selection advice and Design-for-Manufacturing (DFM) analysis, to mold development and mass production molding, Jvtech Silicone is committed to providing medical device customers with practical, one-stop solutions, helping products meet safety and regulatory requirements while accelerating their journey from design to market.

For further insights into the practical applications of medical-grade LSR in respiratory therapy, implantable devices, and other medical uses, we invite you to contact and consult with the professional team at Jvtech Silicone.