Table of Contents

ToggleProject Background

Service: Mold processing and product production

Material: LSR70A + LSR Conductive Silicone 40A

Color: Natural (transparent) + black

Quantity: 1 set

Delivery Time: 45 days

Client

Green Island Traditional Chinese Medicine International Group Co., Ltd. is an international modern Chinese medicine enterprise integrating scientific research and development, production, sales, and medical services. It was registered in Hong Kong in 2006. The company is dedicated to the perfect combination of traditional Chinese medicine and modern science and technology, developing modern Chinese medicine, health food, medical health equipment, etc. Its products include Chinese patent medicines, health foods, medical health equipment, and have achieved a series of research results and technical patents in various fields.

The production base of Green Island Traditional Chinese Medicine International Group’s Chinese medicine and health food is located in the Hunchun Border Economic Cooperation Zone at the border of China, North Korea, and Russia. It obtained GMP certification in 2006. The company also has a production base for Chinese medical equipment in Fenggang Town, Dongguan City.

The group takes technological innovation as the guide, combines traditional Chinese medicine with modern science and technology, and strives to pioneer a ‘blue ocean’ in the broad field of human health, creating a cross-disciplinary health industry development space suitable for the 21st century.

Product

Conductive Technology: Unique conductive design effectively promotes blood circulation, accelerates metabolism, soothes fascia, and relieves fatigue.

Healthy Material: Made of food-grade silicone, safe and non-irritating, soft and fit, not easy to damage, reusable, and durable.

Exquisite Craftsmanship: Meticulously crafted with smooth edges that do not hurt the skin, making it safer to use.

Multifunctional Application: Functions include tapping, vibration, and massage. It can be used on the neck, back, waist, and other parts to relieve muscle soreness, improve physical discomfort, and provide an all-around comfortable experience.

Conductive Silicone

Conductive silicone is a material that evenly distributes conductive particles in silicone, giving it conductive properties. Conductive silicone is usually made of conductive particles such as silver-coated copper powder or nickel-coated graphite powder. These conductive particles contact each other to achieve conductivity.

The main characteristics of conductive silicone are:

– Conductivity: Capable of conducting electricity, applicable in electronics and electrical fields.

– Sealing and Electromagnetic Shielding: Some conductive silicones also have sealing and electromagnetic shielding functions.

– Stability: Stable performance, not prone to blackening.

– Flexibility: Certain flexibility, suitable for applications requiring bending or deformation.

Conductive silicone is widely used in the following areas:

– Electronic Products: Conductive connections for circuit boards, connectors, keyboards, etc.

– Conductive Pads: Used in electronic devices as conductive pads, providing conductivity and cushioning.

– Medical Devices: Used in medical devices such as physiotherapy electrodes for current transmission.

– Sealing and Shielding: Used in applications requiring sealing and electromagnetic shielding, such as electronic device enclosures.

Silicone

Silicone has good elasticity and flexibility, able to return to its original shape after stretching and deformation. It has good chemical stability, can withstand high and low temperatures, and maintain performance over a wide temperature range. It also has good insulating and sealing properties.

In appearance, silicone can be made transparent or in various colors. Its surface has moderate friction, providing a comfortable feel.

These characteristics make silicone widely used in many fields, such as kitchenware, electronic products, medical, beauty, etc. It is also important in the automotive and aerospace industries. With technological advancements, silicone materials continue to improve and innovate to meet different needs and application scenarios.

Mold Design

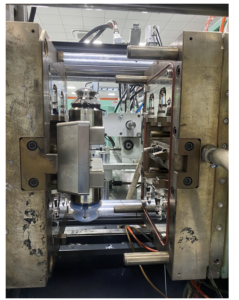

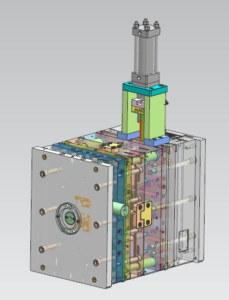

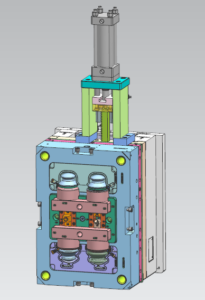

This conductive jar is produced on a 160T LSR horizontal 2-shot silicone machine. The mold design scheme uses a rear mold rotating structure, first forming the black conductive ring, then the ejection pin is driven by an oil cylinder to rotate the rack, rotating the ejection pin 180 degrees to form the jar body, and finally, the product is demolded by air blowing.

Our Mold Processing Workflow

- Receive product drawings

- Drawing review

- Customer confirmation (DFM report)

- Mold design

- 3D/2D mold drawing confirmation

- Mold core steel material ordering

- Mold base purchase (fully 3D)

- Loose parts purchasing

- Send mold core 3D drawings to CNC machining center

- Send 2D drawings to mold shop

- Rough CNC machining of mold core

- Rough lathe machining of inserts

- Milling and drilling tapping

- Heat treatment of mold core and inserts

- Grinding machine processing

- Precision CNC machining of mold core

- Precision lathe machining of inserts

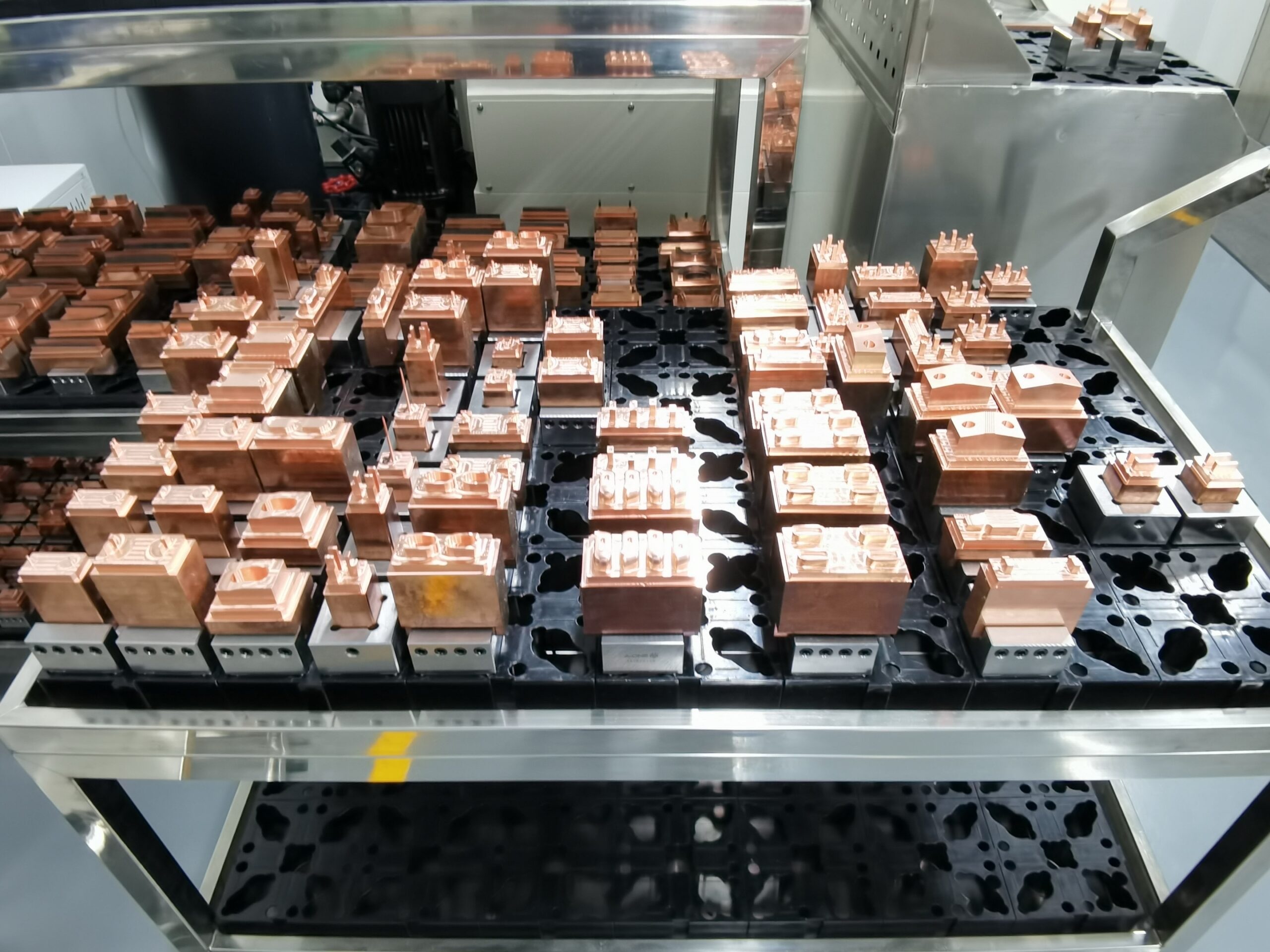

- CNC machining of electrodes

- EDM discharge machining

- Wire cutting processing

- 3D measurement of mold core

- Parts processing

- Mold assembly

- Polishing

- Texture application

- Mold installation

- Trial mold

- Sample delivery