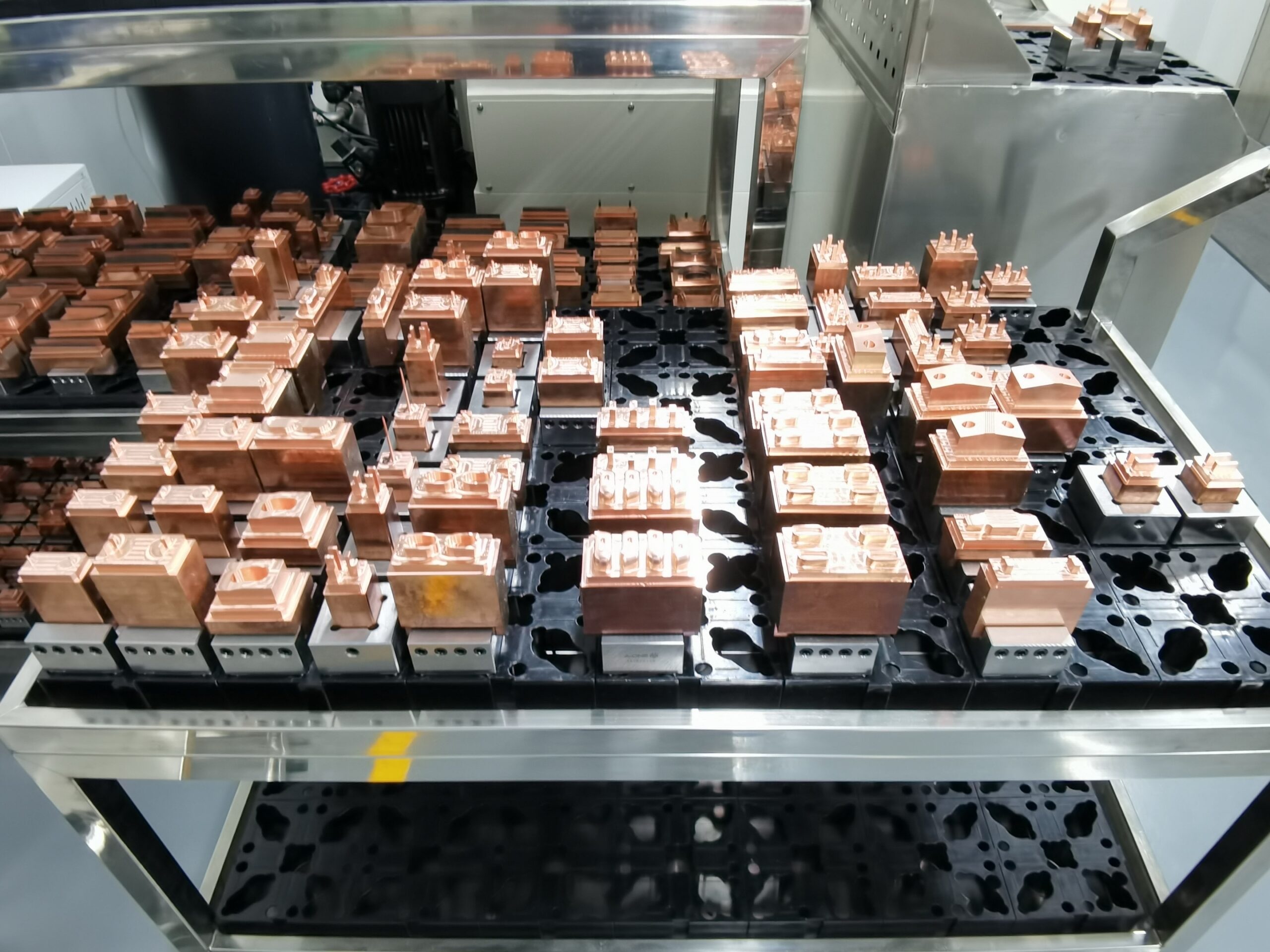

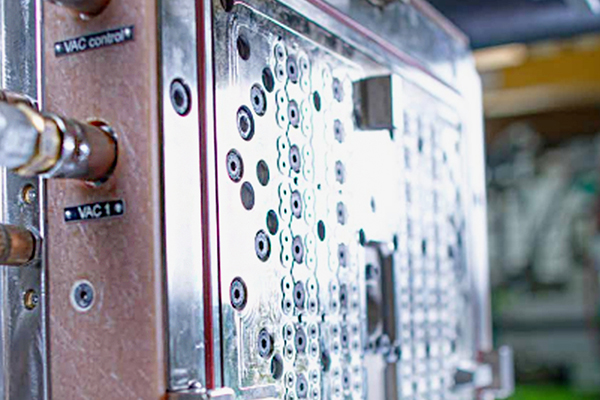

Many injection molding parts are made using single-cavity tooling. That is, each mold core and cavity is designed to produce a single component for each shot of molten plastic. But this doesn’t have to be the case. Some molds contain multiple cavities, which means that multiple components can be formed with each shot of plastic.

Multi-cavity mold contains multiple cavities of the same part. They are used for mass production of single components, and symmetry is usually used to ensure that each identical cavity is evenly filled. The number of mold cavities depends on the size of tools, the size of parts and the requirements of customers. The mold may contain two to 128 cavities. Our engineering team has achieved 84 cavities for optical parts.

Improved production efficiency

Reduced long run production cost

Consistent part quality

Faster turnaround time

Reduced mold quantity

Resource optimization

Simplified production setup

Meeting large-scale demands